Robot hands aren’t just metal and motors—they’re tiny geniuses learning to touch and grip like humans. Advanced neural networks and microscopic sensors let them sense pressure, texture, and temperature with insane precision. Think soft silicone fingers, carbon fiber bones, and AI brains that learn from every single touch. They can now handle everything from microsurgery to strawberry picking without breaking a sweat. Curious how deep this robotic rabbit hole goes?

The Mechanical Architecture of Robotic Hands

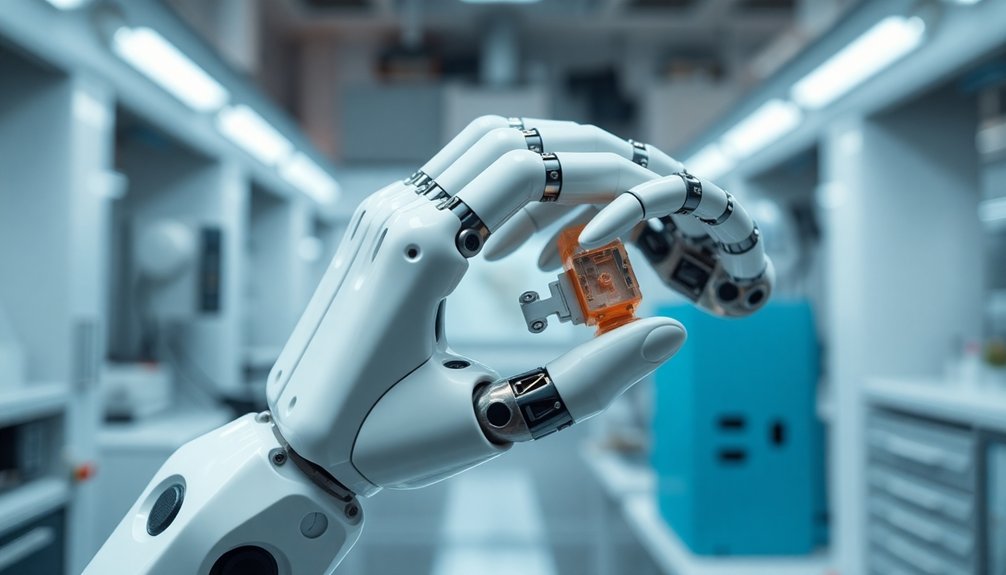

Mechanical marvels of engineering, robotic hands are more than just fancy metal contraptions—they’re sophisticated mimics of human anatomy.

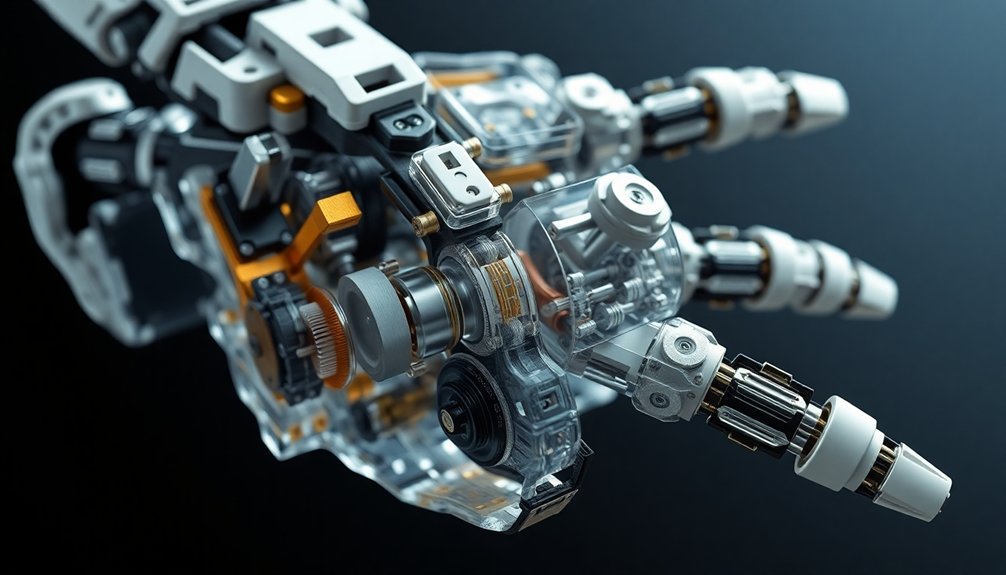

When you peek under the hood, you’ll see a complex mechanical architecture that’s basically anatomy meets high-tech robotics. These hands aren’t just rigid frameworks; they’re dynamic systems with multiple joints and incredible degrees of freedom.

Think of them like hyper-precise puppets, where each movement is calculated and intentional.

Sensory capabilities like tactile sensors transform these robotic hands from mere machines into intelligent tools.

Electric actuation systems provide the muscle, allowing for precision movements that can range from crushing a steel can to picking up a delicate egg.

The result? Robotic hands that don’t just move—they perform with surgical accuracy. Electromechanical actuators enable these intricate movements by converting electrical energy into precise mechanical actions, simulating the complexity of human muscle movement.

Sensing Beyond Vision: Tactile Intelligence

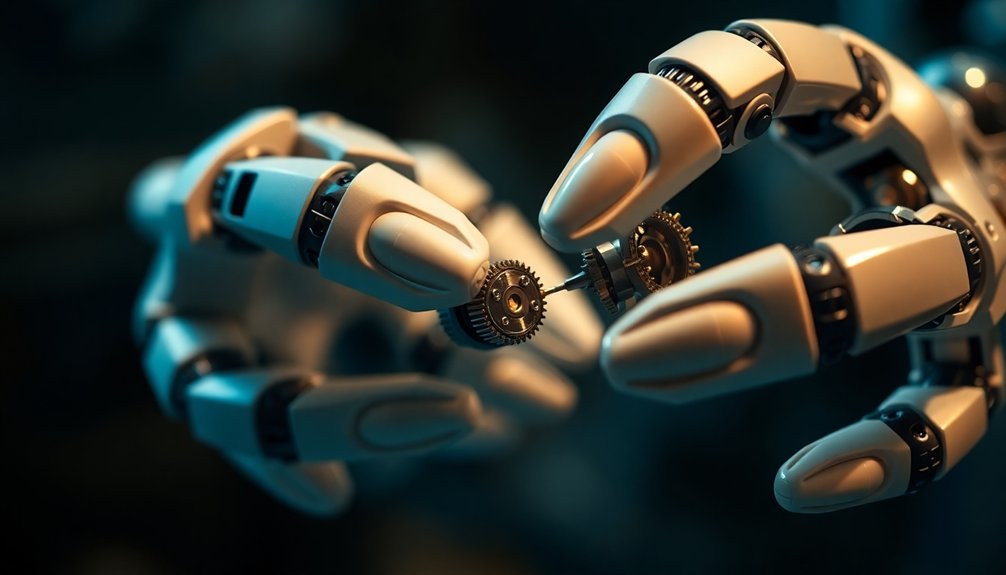

The secret sauce of modern robotics isn’t just about what these mechanical hands can see—it’s about what they can feel. Tactile intelligence transforms robot hands from clumsy grabbers into precision instruments that sense pressure, texture, and temperature with mind-blowing accuracy. Triboelectric neural networks enable robots to recognize material properties through sophisticated electrical signal interpretation, achieving up to 97% accuracy in touch-based object identification. These aren’t your grandpa’s robotic grippers; they’re learning machines that adjust grip strength in milliseconds, thanks to deep reinforcement learning algorithms that let them explore manipulation tasks like curious toddlers. Imagine a hand that can handle a delicate egg or grip a rough tool without visual cues—that’s the magic of sensory feedback. By processing complex tactile data, these robotic appendages don’t just interact with objects; they understand them, adapting and learning with each touch.

Motor Learning and Algorithmic Precision

You’ve probably wondered how robot hands go from clumsy metal contraptions to precision instruments that can practically learn motor skills faster than you can binge a Netflix series.

Deep reinforcement learning lets these mechanical marvels explore movement strategies at hyperspeed, fundamentally compressing years of practice into hours of algorithmic exploration. Neural network adaptations enable robots to transform raw sensory data into intelligent, precise motor actions through continuous learning and optimization.

Algorithmic Motor Exploration

While most humans struggle to learn a new skill in weeks, robot hands can master complex manipulations in mere hours through algorithmic motor exploration. Your robotic hand isn’t just a machine—it’s a learning marvel that devours dexterity like a hungry algorithm. Reinforcement learning techniques enable robots to absorb experiences and refine motor skills autonomously, transforming mechanical movements into precise actions. Motor learning techniques allow these mechanical marvels to explore movement strategies with lightning speed, using reinforcement learning to crack complex tasks in record time. Imagine a hand that adjusts grip strength and movement patterns on the fly, powered by tactile feedback and proprioceptive data. It’s not magic; it’s precision engineering. These robotic appendages simulate years of practice in hours, transforming clunky movements into surgical-level control. Who needs human limitations when you’ve got an algorithm that learns faster than you can blink?

Tactile Learning Strategies

Your robot’s advanced tactile sensors aren’t just collecting data—they’re decoding complex textures and pressures in real-time, enabling precision movements that rival human dexterity. Sensor fusion technologies combine multiple sensory inputs to enhance the robot’s understanding of physical interactions, creating a more sophisticated learning environment.

By integrating proprioceptive data with algorithmic learning, these mechanical marvels can simulate years of practice in mere hours, mastering dexterous tasks with uncanny efficiency.

Imagine a robotic hand that learns through touch, adjusting its grip and technique instantaneously—no visual cues needed.

It’s not science fiction; it’s the cutting edge of robotic manipulation.

Each interaction becomes a learning opportunity, with sensors translating physical feedback into intelligent motor strategies that continually refine and improve performance.

Bridging Simulation and Physical Manipulation

Imagine a robot hand that learns faster than you’d chug a triple espresso.

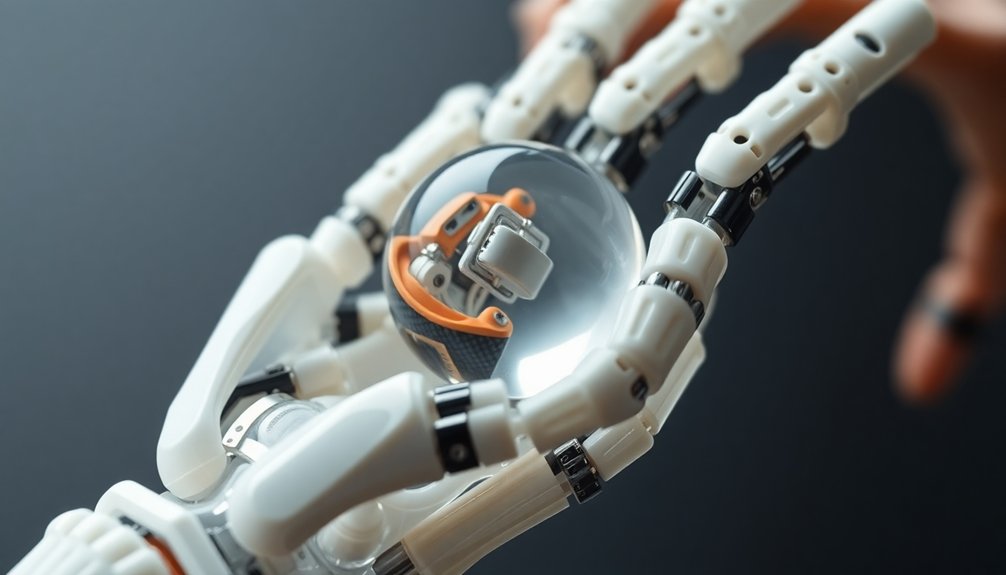

Through deep reinforcement learning, this mechanical marvel mimics the dexterity of human hands, transforming simulation into real-world precision.

Its advanced touch-sensing capabilities let it master manipulation tasks with jaw-dropping accuracy, transferring skills learned in virtual environments to physical challenges. Neural network algorithms enable the robot to continuously optimize its movement strategies through high-frequency sensor feedback and digital trial-and-error learning.

Advanced Materials Enabling Dexterous Movement

You’ve probably wondered how robot hands might actually feel and move like human hands, right?

Smart materials are the secret sauce, turning rigid machines into flexible performers that can grip a raw egg or a power tool with equal grace.

From silicone rubber that stretches like skin to sensors that respond faster than your nervous system, these advanced composites are transforming robotic manipulation from clunky mechanical arms into something that looks suspiciously like magic.

Soft Robotic Materials

When traditional robotic hands seemed more like clunky metal pincers than nimble tools, soft robotic materials emerged as a game-changing solution.

These advanced materials transformed dexterity by mimicking human-like flexibility. Imagine a robot hand that can gently cradle an egg without crushing it or manipulate delicate surgical instruments with precision.

Soft robotic materials enable this magic through compliance mechanisms and variable stiffness that adapt to different objects.

Smart Flexible Sensors

Because robots need more than just brute strength, smart flexible sensors have become the secret sauce in creating hands that can actually feel and respond like living appendages.

These advanced tactile sensors deliver sub-millimeter precision, letting robotic hands detect surface forces and adjust dynamic grip strength on the fly. Imagine sensors wrapped in silicone rubber that can sense pressure, temperature, and texture across complex multi-curved surfaces—basically giving machines a superhuman sense of touch.

The magic? Low wire count and compact designs that enable seamless integration into robotic hands. With such flexibility and adaptability, these sensors transform clunky machines into delicate task masters, capable of handling everything from fragile glassware to intricate mechanical components.

Machine learning algorithms continuously enhance these sensors’ ability to interpret and adapt to diverse environmental inputs, improving robotic perception and interaction capabilities.

Who said robots can’t have a gentle touch?

Precision Composite Structures

If you’ve ever wondered how robots might someday handle a delicate porcelain teacup without turning it into dust, meet precision composite structures—the secret sauce of robotic dexterity.

These advanced materials like carbon fiber and silicone rubber transform robot hands from clunky metal contraptions into nimble, almost-human appendages. Soft robotics principles mean these structures can flex, bend, and adapt to different shapes like a chameleon changing colors.

3D printing lets engineers craft intricate finger geometries that traditional methods couldn’t dream of achieving. Embedded tactile sensors provide real-time feedback, allowing robotic hands to sense pressure and texture with surprising subtlety.

It’s like giving robots a nervous system—minus the drama of actual pain. Who knew materials science could make machines this graceful?

Sensor Technologies Powering Fine Motor Control

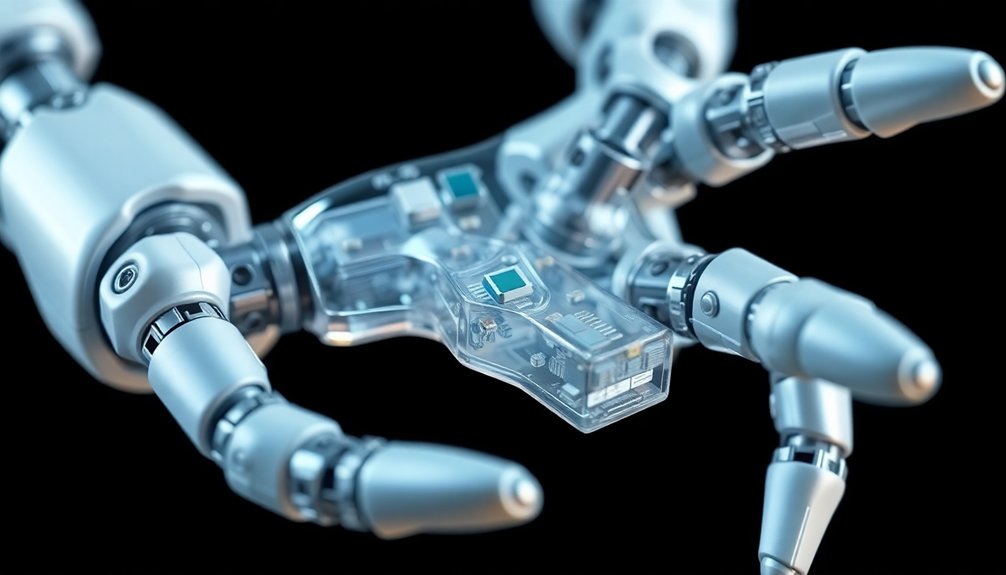

Ever wondered how robots are getting so good at handling delicate objects without crushing them? It’s all about sensor technologies that give robotic hands superhuman precision. Neural network algorithms enable these sensors to process complex sensory information with remarkable speed and accuracy.

Tactile sensors create a sophisticated feedback loop, letting AI algorithms process sensory data in milliseconds. Pressure sensors detect exactly how much grip strength is needed, while temperature sensors help robots handle everything from ice cubes to hot ceramics.

These tiny technological wizards enable sub-millimeter contact localization, transforming clunky mechanical limbs into nimble, intelligent appendages. Think of it like giving robots spider-sense: they can feel texture, pressure, and heat, then instantly adjust their movements.

The result? Dexterity that makes human hands look like prehistoric tools. Who knew robots could be so delicately precise?

From Abstract Intelligence to Embodied Performance

When robotic intelligence transforms from abstract algorithms to physical performance, something magical happens. Robotic hands evolve from clunky machines to precision instruments, dancing through complex motor strategies with jaw-dropping dexterity. Who knew algorithms could choreograph such elegant movements? Neuromorphic computing architectures enable robots to learn and adapt their motor skills with unprecedented organic intelligence.

| Sensor Input | Processing | Embodied Action |

|---|---|---|

| Tactile Data | Deep Learning | Precise Manipulation |

| Proprioception | Abstract Intelligence | Human-like Movements |

| Weight/Texture | Skill Transfer | Adaptive Grip |

Your robotic companion learns through sensory inputs, translating abstract intelligence into tangible performance. Imagine a hand that can grip an egg or shuffle cards with surgical precision—that’s the promise of embodied intelligence. These aren’t just machines; they’re learning systems that adapt, feel, and respond. With 15 independently actuated joints mimicking human-like movements, robotic hands are rewriting the rules of what’s possible. The future isn’t just coming—it’s already gripping reality, one subtle movement at a time.

Real-World Applications Driving Robotic Hand Innovation

How do you transform a robotic hand from a cool lab experiment into something that actually solves real-world problems? By making them dexterous enough to tackle tasks humans find tricky.

Robotic hands are now crushing it in agriculture, gently harvesting delicate fruits without turning them into juice. Their AI systems and machine learning capabilities let them adapt on the fly, using tactile sensing to adjust grip strength in milliseconds.

Imagine a robot that can sew intricate patterns or handle fragile manufacturing components with surgical precision. These aren’t sci-fi fantasies—they’re happening right now.

Companies like Festo are designing soft, flexible hands that collaborate seamlessly with humans. Real-time feedback from over 120 sensors means these robotic hands aren’t just mimicking human movement—they’re often doing it better.

Sensor fusion and adaptive control technologies enable these robotic hands to process complex environmental data instantaneously, transforming how machines interact with delicate tasks and intricate environments.

People Also Ask About Robots

What Is the Science Behind the Robot Hand?

You’ll harness advanced actuators, sensors, and machine learning algorithms that mimic human anatomy, enabling your robotic hand to dynamically adjust grip, interpret tactile feedback, and execute precise movements with remarkable dexterity.

Why Are Robots More Precise?

Like a Swiss watch’s meticulous mechanics, you’ll find robots’ precision stems from tireless sensors, advanced algorithms, and consistent motorized joints that don’t fatigue, enabling them to execute tasks with mechanical perfection beyond human capabilities.

What Is the Most Dexterous Robot Hand?

You’ll find the Shadow Dexterous Hand the most dexterous, boasting over 120 sensors, 24 degrees of freedom, and human-like functionality that enables complex manipulation tasks with unprecedented precision and adaptive movement.

What Is Dexterity Robotics?

You’ll hit the nail on the head with dexterity robotics! It’s a cutting-edge field where robotic hands mimic human-like manipulation skills, using advanced sensors, machine learning, and precise mechanical designs to interact with objects seamlessly.

Why This Matters in Robotics

You’ve watched robot hands evolve from clumsy metal pincers to nimble digital dancers. They’re not just tools anymore—they’re extensions of computational imagination, bridging silicon intelligence with physical grace. As sensors get smarter and materials more responsive, these mechanical marvels will keep pushing boundaries. The future isn’t about replacing human hands, but expanding what’s possible when precision meets creativity. Robotics isn’t just technology—it’s poetry in mechanical motion.