Table of Contents

Humanoid robots cost more than luxury cars because they’re basically mobile supercomputers with legs. We’re talking crazy-complex sensor systems, precision actuators, and AI brains that make Tesla look like a toy. Right now, these robots can run over $1 million, but manufacturing innovations and investment are pushing prices down. By 2030, we’ll likely see costs drop to around $15,000 — turning sci-fi dreams into affordable reality. Curious about the robot revolution?

The Staggering Price Tag of Advanced Robotics

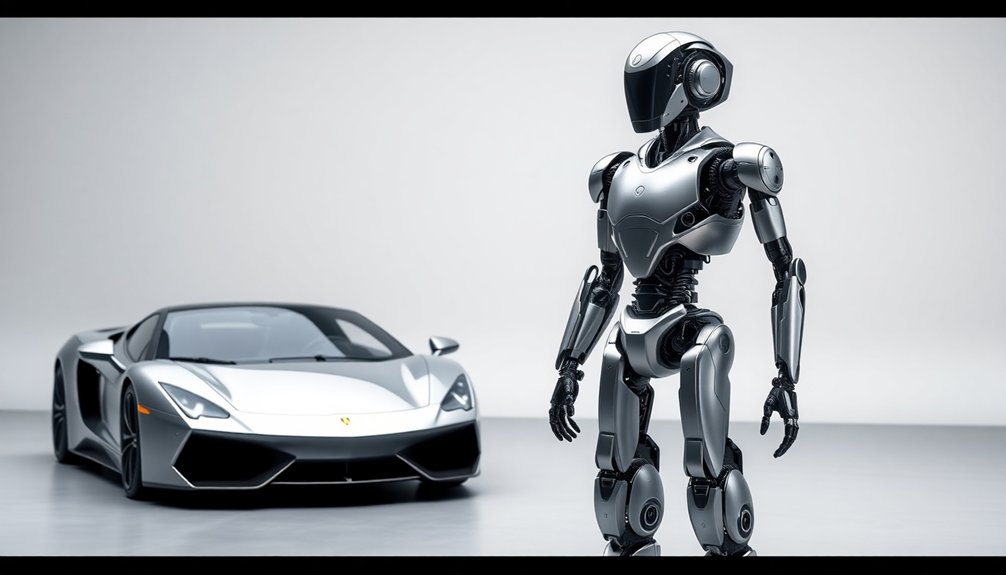

Sticker shock meets sci-fi reality: humanoid robots aren’t just expensive; they’re wallet-obliterating machines that cost more than most luxury sports cars.

We’re talking about cutting-edge technology where a single robot can easily outprice a Ferrari, thanks to mind-blowing complexity in humanoid robot applications. Advanced manufacturing techniques are driving costs down from $50,000-$250,000 to potentially $13,000-$17,000 by 2030. Advanced sensors, multi-degree robotic limbs, and AI processors create perfect storms of astronomical pricing. Venture capital investments of over $7 billion in robotics during October 2024 have further fueled the development of these high-cost technological marvels. Advanced robotics market projections suggest the global market will grow from $34.90 billion in 2024 to $41.51 billion in 2025, indicating massive technological investment.

Sci-fi tech meets wallet destruction: humanoid robots surge past supercars in breathtaking, budget-crushing complexity.

Industry collaboration hasn’t yet cracked the code to mass production, leaving each robot as a custom-engineered marvel. Precision motors, lightweight carbon fiber materials, and next-level robotic vision technologies like multi-spectral imaging and facial recognition algorithms contribute to their astronomical costs.

Just imagine: one humanoid robot could potentially cost you $1 million or more—and that’s before you even start thinking about maintenance and upgrades.

Breaking Down Humanoid Robot Manufacturing Costs

While most people think robots are just fancy toys for tech geeks, the real story of humanoid robot manufacturing costs is way more complex than anyone imagines. Goldman Sachs reports that robot manufacturing costs have dramatically decreased from $50k-$250k to $30k-$150k within a single year. With advanced sensor technologies driving component complexity, manufacturers must carefully balance performance and affordability. Precision actuator engineering plays a crucial role in defining the intricate mechanical capabilities that separate advanced humanoid robots from simple machines. We’re talking serious cash here – between material choices, sensor technologies, and precision engineering, these mechanical marvels cost more than some luxury cars. The price tag isn’t just about fancy parts; it’s about robot maintenance and meeting growing consumer demand. Neuromorphic computing systems enable these robots to process complex interactions, adding another layer of technological sophistication to their already impressive capabilities. Each component – from high-tech depth cameras to ultra-precise actuators – drives costs sky-high. But here’s the kicker: experts predict prices will nosedive by 2035, potentially dropping to around $13,000. Innovation and manufacturing efficiency are our secret weapons, slowly making these robotic dreams more affordable for everyone. Who knew the future could be this exciting?

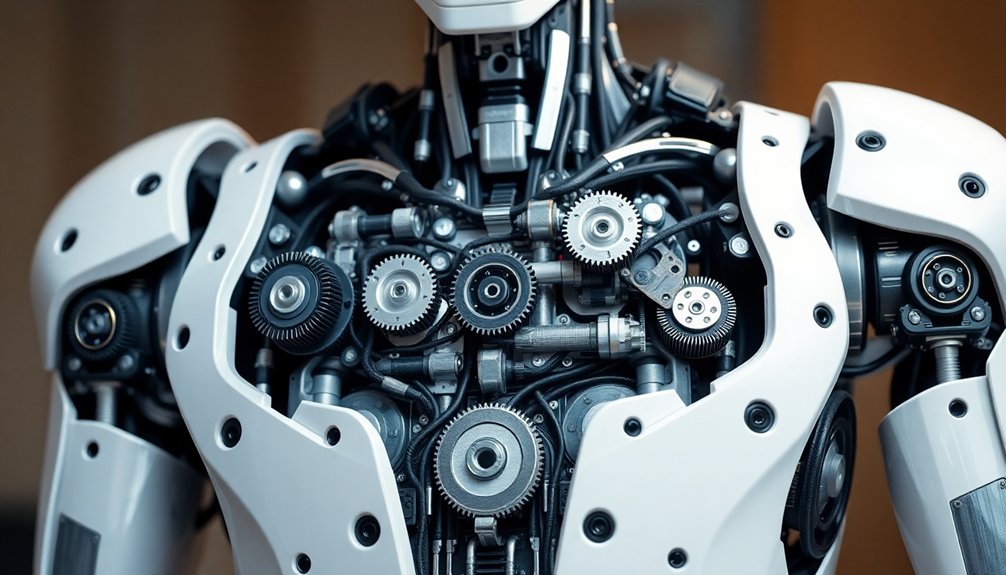

Why Complex Components Drive Astronomical Prices

We’re talking serious tech here: the kind of robotic components that make a Tesla look like a toy tricycle. Advanced industrial robots costing up to $100,000 industrial robot prices reveal the astronomical investments required to create sophisticated machine intelligence. Advanced sensors, precision actuators, and mind-blowing computing systems aren’t just adding complexity—they’re fundamentally turning humanoid robots into mobile supercomputers with muscles. The Unitree G1’s advanced electronics, featuring an 8-core high-performance CPU and optional NVIDIA Jetson Orin, exemplify the cutting-edge technology driving these incredible machines. When you start looking at the raw engineering required to make a machine move like a human, you’ll quickly understand why these robots cost more than most people’s houses. The projected BOM cost decline of over 50% in components by 2030 demonstrates the massive technological and economic transformations happening in humanoid robotics manufacturing.

Advanced Sensor Technology

Robot nerds, buckle up: those mind-blowing humanoid robots aren’t just complex machines—they’re basically walking, talking sensor symphonies that cost more than a Ferrari.

Sensor innovations are driving costs through the roof, with each high-tech component reading the world like a supercomputer with legs. We’re talking force sensors that measure microscopic movements, tactile sensors detecting textures finer than a whisper, and vision sensors that practically see around corners.

Resense miniature 6-axis force/torque sensors are critical robotic components that provide precise touch feedback and enhance machine interaction capabilities in advanced robotics. The LiDAR sensor technologies like SLAMTEC Aurora integrate multiple perception systems, exponentially increasing robotic sensing complexity and cost.

Market competition might eventually drive prices down, but right now, these sensors are so precise and specialized that they’re basically robotic superpowers.

Imagine needing cameras, motion trackers, and touch feedback just to walk across a room—that’s why these mechanical marvels cost more than most luxury vehicles. Not cheap, but definitely mind-blowing.

Precision Robotic Actuators

From sensing the world to moving through it, humanoid robots demand components so precise they’d make a NASA engineer blush.

We’re talking precision actuator types that transform robotic movement from clunky to eerily human-like. Electric and stepper actuators pack serious performance, using advanced materials like CFRP that make these mechanical muscles lighter and stronger than ever. Take the RMD-X10 V3, with its high-torque robotic capabilities, representing the pinnacle of precision engineering. These actuators leverage linear motion technologies that enable unprecedented mechanical efficiency.

Sure, each custom joint costs more than some people’s monthly rent – but that’s the price of innovation.

Actuator material advancements are slowly driving down costs, but right now we’re looking at components that are basically robotic jewelry: beautifully engineered, wickedly expensive, and absolutely essential for creating machines that can walk, grab, and mimic human motion with breathtaking accuracy.

Complex Computing Systems

Because turning a hunk of metal into a thinking, moving machine isn’t child’s play, the computing systems inside humanoid robots cost more than some people’s entire college education. We’re talking serious computational efficiency that demands specialized integration techniques to make these mechanical marvels work.

| Computing Component | Cost Impact |

|---|---|

| AI Chips | High |

| Multi-Core Processors | Extreme |

| GPU Accelerators | Significant |

| Real-Time OS | Critical |

Each robot requires a brain that can process sensory data, learn from experiences, and make split-second decisions. We’re basically building a supercomputer that can walk, talk, and potentially judge your fashion choices. The result? Computing systems that drive prices into stratospheric territory, making luxury cars look like bargain-bin toys. Who said creating intelligence was cheap?

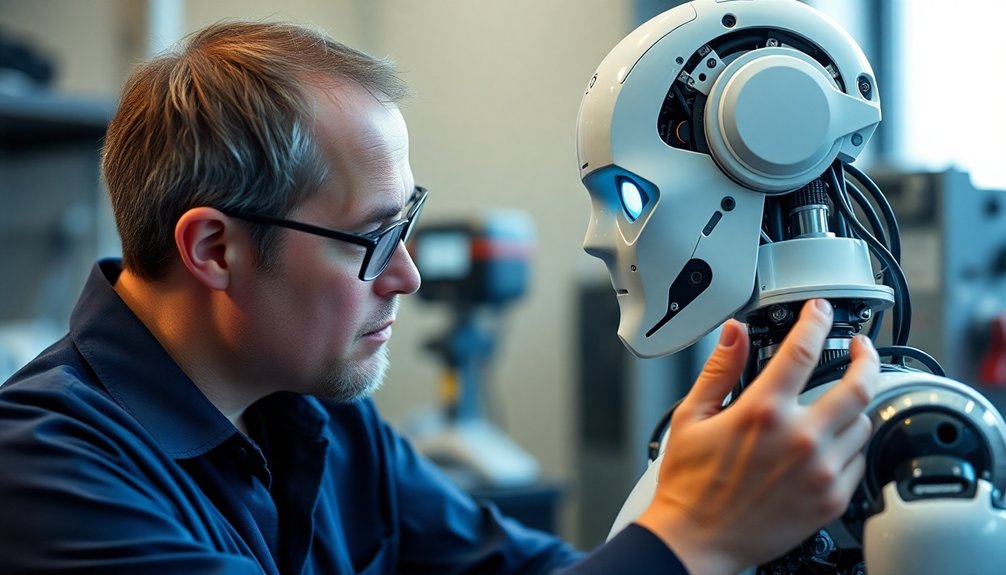

Research and Development: The Hidden Expense

We’ve seen how engineering a humanoid robot isn’t just expensive—it’s like building a rocket-powered Swiss watch that can walk and talk.

The sheer complexity of prototype development means pouring millions into creating machines that can navigate our messy human world, with each iteration costing more than some people’s entire lifetime earnings.

Our innovation investment isn’t just about metal and circuits; it’s about pushing the boundaries of what technology can achieve, even if that means burning through research budgets faster than a silicon valley startup.

Engineering Complexity Costs

While most people imagine robots as shiny, affordable gadgets, the engineering complexity behind humanoid robots tells a different story. The cost breakdowns reveal staggering engineering challenges that make these machines more expensive than luxury cars. Advanced materials, precision components, and sophisticated mobility systems drive prices skyward.

| Component | Complexity | Cost Impact |

|---|---|---|

| Actuators | High | $$$$$ |

| AI Systems | Extreme | $$$$$ |

| Sensors | Advanced | $$$$$ |

We’re talking about robots that require custom-engineered parts with mind-blowing precision. Think microscopic gears that cost more than most people’s monthly rent, software that’s fundamentally a PhD-level brain, and power systems so complex they make rocket science look like child’s play. Each robotic system is fundamentally a mobile supercomputer with legs – and that doesn’t come cheap.

Prototype Development Expenses

If you think building a humanoid robot is just another engineering project, prepare for a reality check that’ll make your wallet weep. Our prototyping techniques reveal that creating these mechanical marvels isn’t cheap. Material innovations help, but we’re still talking serious cash.

Advanced sensors, complex mechanical systems, and cutting-edge software create a perfect storm of astronomical expenses. We’re burning through millions just to get a robot that can walk without falling over. Highly skilled engineers don’t come cheap, and each iteration means more dollars down the drain.

Specialized components cost more than some luxury cars, and that’s before we even talk about software development. Want a humanoid robot? Better start saving—or find a very generous investor.

Innovation Investment Required

Behind every mind-blowing humanoid robot lies a financial black hole that would make venture capitalists nervous. Innovation’s price tag is astronomical, and we’re not talking chump change.

- Advanced AI software costs more than some people’s annual salary

- Precision components demand engineering wizardry

- High-end lab equipment looks like sci-fi movie set pieces

- Continuous research burns through millions like rocket fuel

Our innovation impact reveals future possibilities that are both thrilling and wallet-crushing. Developing these mechanical marvels isn’t just expensive—it’s a complex dance of cutting-edge technology, precision engineering, and relentless iteration.

We’re fundamentally building the closest thing to artificial life, and that doesn’t come cheap. Every robotic breakthrough represents thousands of hours of research, failed prototypes, and breakthrough moments that transform science fiction into tangible reality.

Comparing Humanoid Robots to Luxury Vehicle Markets

As the tech world continues its wild dance of innovation, humanoid robots are stepping onto the stage with price tags that’ll make luxury car enthusiasts do a double-take.

While luxury vehicles boast sleek designs and premium features, humanoid applications are emerging as the new status symbols of technological prowess.

We’re talking robots that cost more than most high-end sports cars, with price points hovering around $200,000 compared to traditional automotive luxury.

The key difference? These robots aren’t just about looking cool—they’re designed to work, delivering productivity across healthcare, defense, and industrial sectors.

Market projections suggest humanoid robots could hit $5 trillion by 2050, making luxury cars look like mere toys in the innovation playground.

Who’s ready for this robotic revolution?

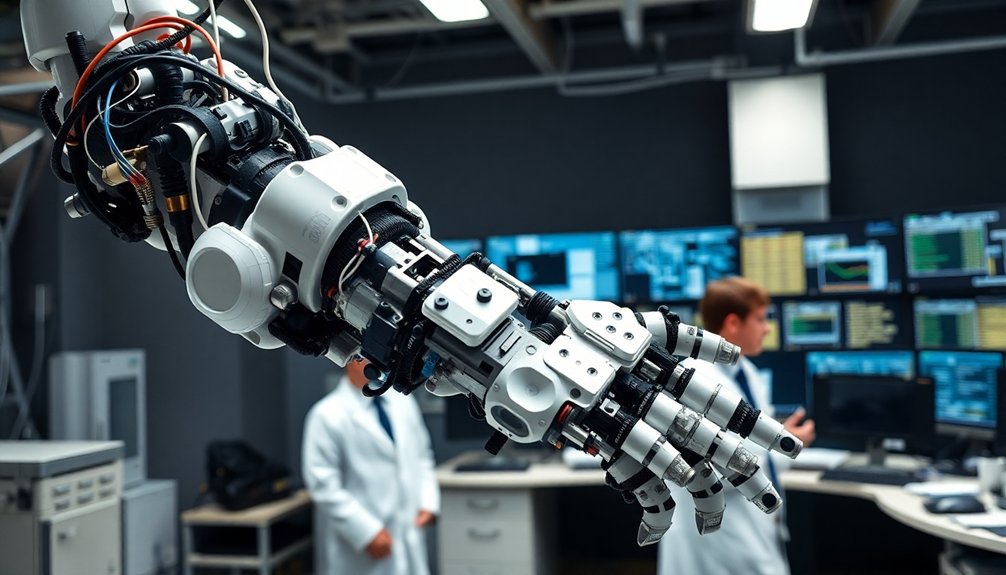

Advanced Sensor and Actuator Technology Explained

We’re talking sensor tech that makes robots move like they’ve got actual muscles and nerves, not just cold metal and circuits.

Our precision engineering transforms humanoid robots from clunky machines into responsive, almost-alive mechanical beings that can sense forces and react faster than you can blink.

Just imagine actuators so complex and intelligent that they can mimic human movement with such accuracy that the line between machine and organic motion starts to blur.

Precision Sensor Engineering

Three critical sensors can make or break a humanoid robot’s performance, transforming these mechanical marvels from clunky machines into something eerily close to human capability.

Precision sensor engineering isn’t just complex—it’s the secret sauce that turns robots from awkward metal puppets into near-sentient beings.

Our sensors are serious business:

- High-resolution cameras that see sharper than human eyes

- Tactile feedback systems mimicking human touch sensitivity

- Advanced calibration techniques tracking microscopic movements

- Real-time environmental perception technology

Sensor calibration is where the magic happens. Imagine a robot that can feel the difference between silk and sandpaper, or detect temperature variations as subtle as a whisper.

These aren’t sci-fi fantasies—they’re today’s engineering realities. We’re pushing technological boundaries, transforming cold machinery into responsive, intelligent systems that can interact with our world in ways we’re just beginning to understand.

Complex Mechanical Actuators

When mechanical muscles meet cutting-edge engineering, humanoid robots transform from clunky metal mannequins into something that’d make science fiction writers jealous. We’re talking about actuators—the robot’s secret sauce of movement, where performance metrics meet pure mechanical magic.

| Actuator Type | Key Performance |

|---|---|

| Electric | High precision |

| Hydraulic | Maximum torque |

| Pneumatic | Flexible motion |

These aren’t just motors; they’re intricate dance partners of technology. Actuator materials like advanced composites and lightweight alloys enable robots to mimic human movement with shocking precision. Imagine strength without bulk, speed without sacrifice—that’s the engineering dream we’re chasing. Companies like Tesla are rewriting the rules, designing custom actuators that turn robotic limbs from stiff mechanisms into fluid, responsive extensions of pure mechanical intelligence.

Advanced Motion Technology

Imagine humanoid robots so precise they could thread a needle while running a marathon—that’s the promise of advanced sensor and actuator technology. We’re talking about robotic systems that can move with shocking grace and intelligence.

- Sensor fusion creates superhuman perception

- Actuator efficiency means robots move smarter, not harder

- Mechanical precision rivals surgical instruments

- Dynamic responsiveness mimics human reflexes

Our latest sensor and actuator technologies transform robots from clunky machines into adaptive, responsive systems.

By integrating high-precision sensors and ultra-efficient actuators, we’re creating machines that can navigate complex environments with near-human agility.

Think of it like giving robots a brain, nervous system, and muscle network that can instantly adapt to changing conditions—all while consuming minimal power. The result? Robots that move so naturally, you might just forget they’re machines.

Current Production Volumes and Their Economic Impact

As the humanoid robot market gears up for a massive transformation, production volumes are telling a story of technological ambition and economic potential. Figure AI is cranking out an ambitious 12,000 robots annually, signaling a shift in market dynamics that’ll make your head spin.

We’re looking at a trillion-dollar industry brewing, with projections suggesting over 1 billion humanoids could be wandering around by 2050. Sounds wild, right? But here’s the kicker: early production is laser-focused on industrial settings where these metal colleagues can work without causing chaos.

The numbers don’t lie — we’re talking about a market expected to hit $38 billion by 2035, which means robots aren’t just sci-fi fantasies anymore. They’re becoming our next economic frontier.

Technological Innovations Driving Future Price Reductions

If robotic price tags are currently making your wallet weep, technological innovations are about to become your new best friend.

We’re witnessing a perfect storm of cost-cutting breakthroughs that’ll make humanoid robots more affordable:

- 3D printing slashing manufacturing complexity

- Open-source software frameworks reducing development costs

- AI-driven robotic enhancements improving efficiency

- Modular designs enabling faster, cheaper prototyping

Advances in materials, sensors, and electronics are dramatically dropping component prices.

AI simulation tools now let us train robots without expensive real-world experiments, while foundation models simplify software development.

Consumer electronics’ technological overlap means cheaper sensors and control boards.

Mass production of actuators and standardized components will further drive down costs.

The Economics of Scale in Robotics Manufacturing

From cutting-edge prototypes to penny-pinching production, humanoid robot manufacturing isn’t just a technical challenge—it’s an economic chess match.

We’re watching a high-stakes game where supply chain complexity and market readiness determine who wins. Right now, these robots cost more than luxury cars, but that’s changing fast.

The robot race: where supply chain wizardry and market smarts create tomorrow’s tech superstars.

As production scales up, we’ll see prices nosedive from $150,000 to potentially $15,000 per unit by 2026. Think of it like early computer prices—massive initial cost, then rapid decline.

Manufacturers are betting big on economies of scale, knowing each robot produced makes the next one cheaper.

It’s not just manufacturing; it’s a technological revolution where every robot rolls off the line slightly more affordable than the last. Cool, right?

Projected Cost Trajectories Through 2032

Picture humanoid robot prices as a rollercoaster with a steep downward slope—and we’re all buckled in for the ride. By 2032, cost reduction isn’t just a dream; it’s a guaranteed trajectory.

- Economies of scale will slam robot prices downward

- Competitive tech innovation becomes our secret weapon

- Mass production strategies are about to get wild

- Component standardization means cheaper, smarter robots

We’re watching a market growth explosion that’ll make early adopters look like visionaries.

Think about it: custom parts driving prices sky-high today will become tomorrow’s mass-produced components. Competition will drive innovation, pushing humanoid robot costs from “luxury car” territory to something closer to a high-end smartphone.

The sweet spot? Between 2029-2032, when manufacturing efficiencies converge and technology matures. Buckle up—this ride’s just getting started.

Market Potential and Investment Trends in Humanoid Robotics

While most people think robots are just sci-fi fantasies, the humanoid robotics market is about to explode into a multi-billion dollar reality that’ll reshape entire industries.

Our market analysis reveals a jaw-dropping trajectory: from niche tech to a potential $243 billion sector by 2035. Investment strategies are heating up, with venture capital and tech giants betting big on AI-powered humanoids.

We’re seeing smart money flow into healthcare, elderly care, and service industries where robots could plug massive labor gaps. The demographic shifts are real—aging populations and workforce shortages are creating perfect conditions for robotic disruption.

Unlike clunky prototypes of the past, today’s humanoids are sophisticated machines poised to transform how we work, care, and interact.

When Humanoid Robots Become Financially Accessible

Because most people think robots cost more than a small country’s GDP, we’re about to shatter some misconceptions about humanoid robot pricing.

- Forget $150,000 price tags

- Humanoid robot affordability is closer than you think

- Future robotic applications will transform economies

- Prices are dropping faster than smartphone costs

We predict humanoid robots will become financially accessible by the mid-2030s.

How? Mass production, technological breakthroughs, and increasing market competition will drive costs down dramatically.

Imagine domestic helpers, industrial assistants, and healthcare companions becoming as common as smartphones.

Government subsidies and expanding global demand will accelerate this transformation.

These aren’t sci-fi fantasies—they’re economic inevitabilities.

As AI and robotics advance, the barriers between human and machine capabilities will blur, making sophisticated robots not just possible, but probable and affordable.

People Also Ask

Can Humanoid Robots Be Repaired if They Break Down?

We can repair humanoid robots through specialized repair services that conduct thorough breakdown diagnostics, though the process is complex and can be expensive due to technical expertise required.

Do Humanoid Robots Require Special Insurance or Maintenance Plans?

We’ll need special insurance with liability coverage and extensive repair warranties for humanoid robots, as their complex technologies and potential risks demand specialized protection beyond traditional equipment insurance.

How Energy-Efficient Are Humanoid Robots Compared to Human Workers?

Imagine circuits humming like a power grid, humanoid robots consume more energy than humans during tasks. We’re less efficient, yet our continuous labor offers unique advantages in energy expenditure and performance.

Are There Financing Options Available for Purchasing Humanoid Robots?

We offer multiple financing options for humanoid robots, including robot leasing and flexible payment plans that help spread out high initial costs across multiple years of predictable investments.

Can Humanoid Robots Be Customized for Specific Industry Needs?

We’ve cracked the code to robot customization! Our cutting-edge humanoid robots deliver industry-specific adaptations and tailored functionalities, revolutionizing sectors from manufacturing to healthcare with precision-engineered, modular design solutions.

The Bottom Line

We’re looking at a robotics revolution that’ll make today’s crazy prices look like pocket change. Tesla’s first electric cars cost a fortune; now they’re mainstream. Similarly, humanoid robots will drop from “millionaire’s plaything” to “everyday tech” within a decade. Take Boston Dynamics: their robots once cost millions, now they’re selling for hundreds of thousands. Our bet? Give it time, and these mechanical marvels will be as common as smartphones.

References

- https://standardbots.com/blog/how-much-do-robots-cost

- https://www.morganstanley.com/insights/articles/humanoid-robot-market-5-trillion-by-2050

- https://hbr.org/2025/05/5-questions-to-ask-before-investing-in-humanoid-robots

- https://www.installbaseforum.com/forums/threads/the-prosumer-model-stays-winning-goldman-sachs-estimates-humanoid-robot-manufacturing-cost-30k-to-150k-per-unit-lets-look-at-the-competition.2505/

- https://www.edge-ai-vision.com/2025/04/humanoid-robots-2025-2035-technologies-markets-and-opportunities/

- https://www.globenewswire.com/news-release/2025/03/13/3041998/28124/en/Advanced-Robotics-Market-Report-2025-2045-Investment-Intelligence-Technology-Research-Analysis-and-Forecasting-Regulatory-and-Strategic-Insights-Competitive-Landscape.html

- https://www.thebusinessresearchcompany.com/report/advanced-robotics-global-market-report

- https://www.statista.com/outlook/tmo/robotics/worldwide

- https://www.nasdaq.com/articles/transformative-rise-global-robotics-2025-market-analysis

- https://www.einpresswire.com/article/810705820/global-advanced-robotics-market-key-trends-market-share-growth-drivers-and-forecast-for-2025-2034