Robot frames are your machine’s digital skeleton—invisible GPS-like coordinate systems that transform clunky hardware into precision instruments. They map X, Y, and Z axes, telling robots exactly where they are and how to move without bumping into things. Think of them as an internal navigation system that transforms robotic arms from random metal appendages into surgical instruments capable of millimeter-perfect tasks. Curious how deep this robotic rabbit hole goes?

What Are Robot Frames?

Think of robot frames like the invisible skeleton that gives robots their spatial superpowers.

These digital coordinate systems are more than just mathematical mumbo-jumbo—they’re how robots understand where they’re and where they’re going. Imagine a GPS, but way cooler and embedded right into a robot’s core.

Robot frames create X, Y, and Z axes that map out a machine’s entire movement potential, letting it dance through complex tasks with precision.

Whether it’s a base frame anchored to the robot’s foundation, a tool frame attached to its gripper, or a world frame tracking its entire workspace, these frames are the unsung heroes of robotic navigation.

They transform raw machinery into intelligent, purposeful movement—turning metal and circuits into something almost alive.

Sensor fusion technologies enable these frames to integrate multiple data points, creating a comprehensive understanding of spatial dynamics and enhancing robotic precision and adaptability.

Types of Coordinate Frames in Robotics

You might think robots just move around randomly, but they actually navigate using precise coordinate frames that act like their internal GPS.

Your robot’s Base Frame is its home base, the Tool Frame is its Swiss Army knife for precision tasks, and the World Frame maps out the entire playground where it operates.

These three frames work together like a team of invisible engineers, making sure your robot knows exactly where it is, what it’s doing, and how to do it with laser-sharp accuracy.

Base Frame Navigation

When robots navigate their world, they don’t just randomly bumble around like lost tourists—they rely on something called a base frame, which is basically their robotic GPS. SLAM technologies help robots create real-time maps and precise localization coordinates, enhancing their base frame navigation capabilities.

Think of it as the skeleton that keeps everything aligned and makes sense of movement. Your robot’s base frame acts like mission control, determining exactly where it’s and how it’ll get where it needs to go.

It’s the ultimate reference point that transforms chaotic motion into precision engineering.

Key base frame superpowers include:

- Anchoring the robot’s entire coordinate system

- Calculating precise movements between points

- Enabling complex task interactions

- Preventing navigational mishaps and errors

Want a robot that doesn’t stumble? Nail that base frame alignment, and watch the magic happen.

Tool Frame Precision

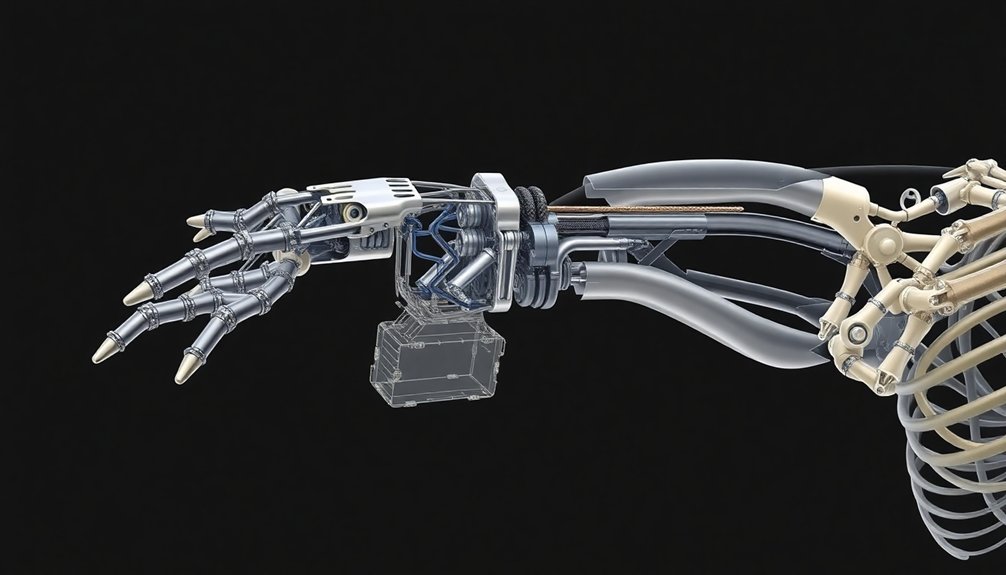

If robots are mechanical dancers, their tool frames are the precision choreography that turns awkward shuffling into breathtaking performance.

You’ve seen robots fumble before—clunky movements that scream “programmed, not practiced.” But tool frame precision changes everything. It’s the secret sauce that transforms robotic arms from random metal appendages into surgical instruments of industrial magic.

Think of a tool frame like the robot’s personal GPS. It tells the machine exactly where its “hand” is in space, allowing for millimeter-perfect positioning during welding, assembly, or delicate manufacturing tasks.

Without this coordinate system, robots would be about as graceful as a toddler with mittens—all intention, zero accuracy. The tool frame isn’t just a feature; it’s the difference between mechanical mayhem and robotic artistry.

Electromechanical actuators transform these precise tool frames into dynamic, responsive movements that simulate human-like precision and adaptability.

World Frame Mapping

While tool frames might be the robot’s personal GPS, world frames are the entire map—the cosmic coordinate system that turns isolated mechanical movements into meaningful interactions.

Think of the world frame as your robot’s existential cheat sheet for understanding its environment. It’s how machines translate local wiggling into global navigation. But why does this matter?

- Robots map their entire workspace

- Transforms local movements into global context

- Enables complex obstacle avoidance

- Facilitates precise environmental interaction

Imagine a robot trying to grab a cup without knowing its actual position in space. Impossible, right?

The world frame gives robots spatial awareness, turning them from blind machines into intelligent navigators. It’s like giving a robot a brain that understands geometry, allowing seamless interaction with complex environments. Depth estimation techniques enable robots to create sophisticated spatial intelligence, mapping their environment with unprecedented precision.

The Right-Hand Rule: Navigating Robot Movements

Because guiding robot movements sounds like a sci-fi puzzle, roboticists developed a simple trick called the right-hand rule.

Picture your hand as a secret navigation system for robot arms. Your thumb points to the z-axis, index finger to x-axis, and middle finger to y-axis. It’s like giving robots a built-in GPS for understanding their own body movements.

Why does this matter? Imagine trying to choreograph a dance without knowing which way is up.

Robots need consistent direction markers to move precisely. The right-hand rule lets engineers communicate complex joint movements with a single hand gesture. It transforms potentially confusing 3D space into a clear, predictable roadmap.

Robotic neural networks use this spatial mapping to analyze and optimize complex movement patterns, allowing for more precise and adaptive locomotion.

How Robot Frames Enhance Industrial Performance

You’ve heard robots aren’t just fancy toys, right?

Robot frames are like the skeletal system that turns a clunky machine into a precision performance artist, giving industrial robots the ability to move with surgical accuracy and repeat tasks without breaking a sweat. Robotic middleware like ROS enables these frames to communicate complex movements and adapt to dynamic industrial environments.

Precision Through Positioning

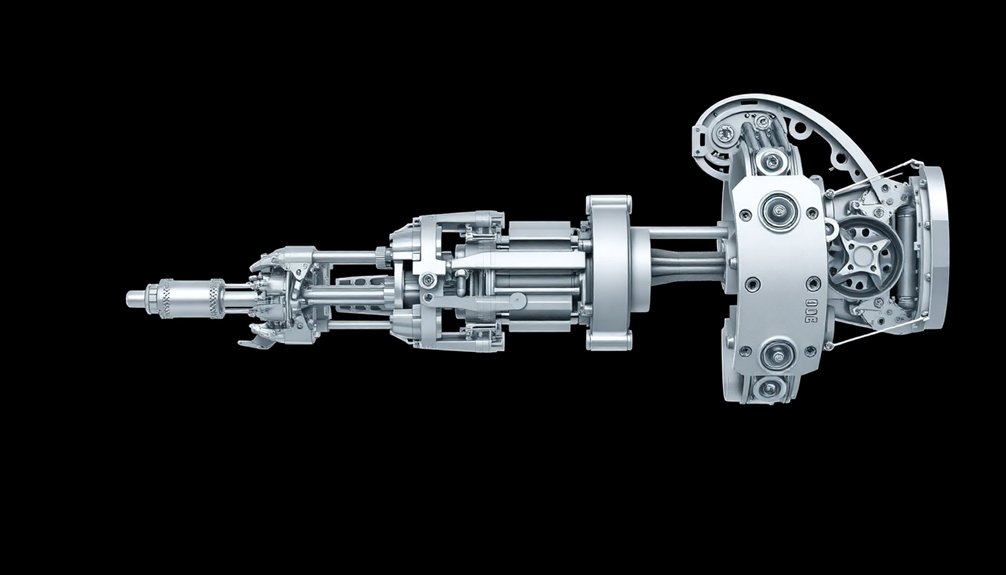

Almost every industrial robot’s secret sauce is its skeleton—the intricate system of coordinate frames that transforms metallic muscle into precision machinery.

You’ve seen robots dance through complex tasks, right? That’s robot frames working their magic behind the scenes.

- Frames define exact spatial relationships

- Coordinate systems translate robotic movements

- Calibration eliminates potential performance errors

- Tool integration becomes seamless and precise

When robot frames are perfectly aligned, they convert raw mechanical potential into surgical-level accuracy.

Imagine a welding robot hitting the same spot within millimeters, every single time. It’s not luck—it’s engineering.

These digital skeletons allow machines to understand their environment, switch perspectives, and execute tasks with mind-blowing consistency.

The result? Manufacturing processes that are faster, more reliable, and dramatically more precise than human hands could ever achieve.

Feedback loops enable these robotic frames to continuously adapt and refine their positioning for unprecedented precision.

Efficiency in Integration

When industrial robots integrate seamlessly into manufacturing lines, it’s like watching a perfectly choreographed dance of metal and precision. Robot frames are the unsung heroes making this magic happen, transforming clunky machinery into surgical instruments of industrial efficiency. Neural network architectures enable these robotic frames to process complex sensory inputs and adapt dynamically to manufacturing challenges.

| Frame Type | Purpose | Benefit |

|---|---|---|

| Base Frame | Positioning Reference | Consistent Movement |

| Tool Frame | End Effector Alignment | Precise Interactions |

| Work Frame | Task Space Definition | Accurate Execution |

| Calibration Frame | Error Minimization | Performance Optimization |

You’ve seen robots swap tools faster than a NASCAR pit crew, right? That’s robot frames in action. They’re not just mechanical skeletons; they’re intelligent coordinate systems that let machines adapt, swap, and execute with mind-blowing precision. Want reliability? These frames are your backstage pass to manufacturing perfection.

Automation Movement Control

Because precision matters more than raw power in industrial automation, robot frames are the silent conductors orchestrating mechanical symphonies across manufacturing floors.

They’re the skeleton that transforms clunky machines into graceful performers of repetitive tasks.

Your robot’s movement isn’t random—it’s a choreographed dance powered by intelligent coordinate systems.

Robot frames enable pinpoint navigation that makes GPS look amateur:

- Translate complex instructions into razor-sharp movements

- Minimize variation between identical industrial operations

- Provide stable reference points for tool positioning

- Facilitate rapid adaptation and tool swapping

Think of robot frames like a gymnast’s muscle memory: consistent, predictable, and surprisingly elegant.

They transform industrial robots from mere machines into precision instruments, turning mechanical potential into calculated performance.

Sensor fusion technologies enhance robot frames’ ability to process real-time environmental data, creating even more sophisticated movement capabilities.

Want perfect repeatability? Your robot’s frame is the unsung hero making it happen.

Engineering Challenges in Robot Frame Design

Robot frame design isn’t for the faint of heart—it’s a precision dance where millimeters can mean the difference between a smoothly operating machine and a catastrophic mechanical meltdown. You’ll need nerves of steel and a brain wired for spatial reasoning. Understanding the tactile sensor complexity reveals how intricate robotic frame design truly becomes when integrating advanced sensing technologies.

| Frame Type | Key Challenge | Solution Strategy |

|---|---|---|

| Base Frame | Alignment | Precise Calibration |

| Tool Frame | Interaction | Simulation Testing |

| World Frame | Complexity | Systematic Mapping |

| Transformation Frame | Error Potential | Proactive Maintenance |

Each coordinate system is like a fragile ecosystem where tiny misalignments cascade into massive operational failures. Your robot’s skeleton isn’t just metal and math—it’s a sophisticated network of interconnected spatial relationships. One miscalculation and your mechanical marvel could transform from precision instrument to expensive paperweight. The secret? Obsessive attention to detail, constant re-evaluation, and a willingness to embrace the complex dance of three-dimensional interactions.

Calibration and Maintenance Best Practices

If precision is the heartbeat of robotics, then calibration is its meticulous cardiologist. You’ll want to treat robot frames like delicate scientific instruments, not rough-and-tumble machinery. Their alignment determines everything from pinpoint accuracy to operational reliability.

Your calibration strategy should include:

- Regular frame re-evaluation to adapt to changing environments

- Simulation tools for pre-implementation visualization

- Proactive maintenance checks

- Detailed attention during multi-frame integration

Think of calibration as your robot’s annual physical. You’re checking its skeletal structure, ensuring each joint and connection communicates perfectly.

One misaligned coordinate can cascade into system-wide errors faster than you can say “robotic malfunction.” Without meticulous calibration, your sophisticated machine becomes nothing more than an expensive paperweight.

Want precision? Then treat calibration like an art form.

Future of Robot Structural Engineering

After meticulously calibrating robot frames down to the micron, engineers are now reimagining the very skeleton of robotic systems. You’ll witness a radical transformation where lightweight materials, biomimetic designs, and artificial muscle technology converge to create robots that move like living creatures.

| Design Feature | Impact |

|---|---|

| Modular Frames | Enhanced Adaptability |

| Lightweight Materials | Increased Efficiency |

| Advanced Sensors | Real-time Performance Monitoring |

| Biomimetic Structures | Improved Agility |

| Artificial Muscles | Smoother Movements |

Imagine robots that can reshape themselves on the fly, sensing environmental shifts and responding with near-organic flexibility. They’ll no longer be rigid machines but dynamic, responsive systems that challenge our understanding of mechanical design. Who’s ready for the next robotics revolution? Your future robotic companions are about to get seriously cool.

People Also Ask About Robots

What Is a Robot Skeleton?

You’ll find a robot skeleton is a structural framework with articulated joints that supports components, enables precise movement, and defines a robot’s position using X, Y, and Z coordinate axes.

What Is the Body Frame of a Robot?

Like a robot’s backbone, its body frame is the structural skeleton that supports components, defines spatial orientation, and enables precise movement across X, Y, and Z axes, giving the machine its fundamental mechanical architecture.

Are They Making Robots That Look Like Humans?

You’ll be amazed – companies like Clone Robotics are indeed creating incredibly human-like robots! The Protoclone V1 features over 200 degrees of freedom, mimicking human anatomy with advanced myofiber muscles and sophisticated sensor systems.

What Is the Most Important Part of a Robot?

You’re the skeleton to a robot’s body—its frame. Like your spine supports movement, a robot’s frame is its core, defining stability, enabling precise navigation, and serving as the critical foundation for all mechanical functions and tasks.

Why This Matters in Robotics

Just like a superhero needs a sturdy skeleton, robots depend on precise frames to conquer complex tasks. You’ve glimpsed the hidden engineering that transforms metal and circuits into intelligent machines. As technology evolves, these robotic skeletons will become more adaptive, more responsive, and increasingly indistinguishable from living systems. The future isn’t about replacing humans—it’s about extending our capabilities in ways we’re only beginning to imagine.