Digital twins are like superhero training simulators for robots, where virtual worlds become risk-free playgrounds for learning complex tasks. Imagine creating a perfect digital clone of a machine that can test thousands of scenarios without breaking anything expensive. IoT sensors and AI transform these virtual environments into hyper-realistic training grounds, letting robots practice disaster responses, manufacturing processes, and tricky maneuvers before stepping into real-world chaos. Curious about the robot revolution?

The Origin of Digital Twin Technology

When NASA engineers faced the Apollo 13 mission crisis, they unknowingly birthed digital twin technology—a game-changing approach to problem-solving that would eventually revolutionize how we comprehend complex systems.

By creating a virtual representation of the spacecraft, they could simulate scenarios and test solutions in real-time, saving lives and setting the stage for future innovations.

Fast forward to the early 2000s, and digital twin technology started transforming manufacturing processes, enabling engineers to predict equipment failures and optimize performance before anything breaks.

Today, IoT sensors and predictive maintenance strategies make these virtual models even more powerful.

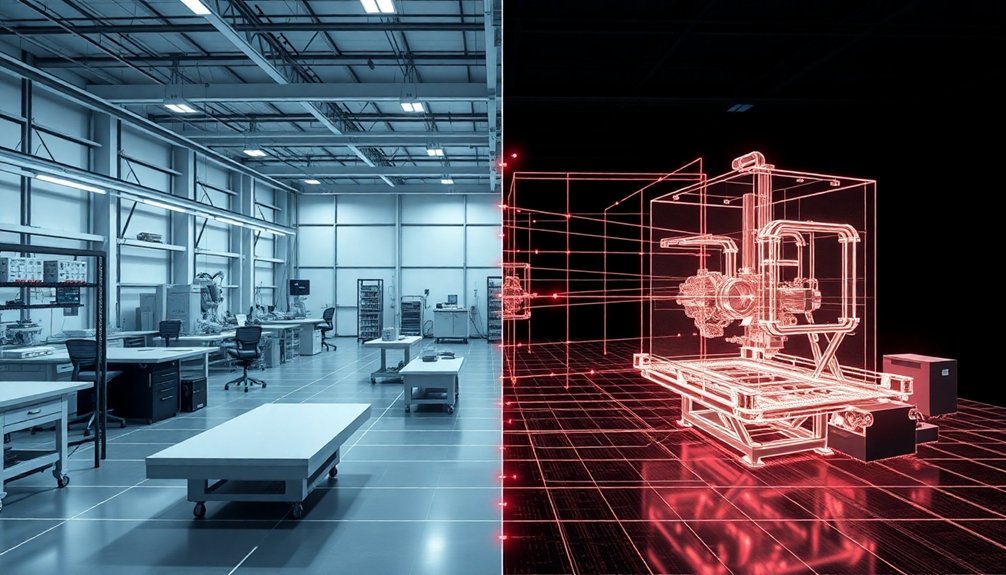

Imagine having a perfect digital clone of a robot, machine, or entire factory—running scenarios, catching problems, and improving efficiency without risking real-world resources.

Pretty cool, right?

How Digital Twins Simulate Physical Environments

Digital twin technology transforms robotic training from risky real-world experiments into precise virtual playgrounds.

Imagine robots learning complex tasks without breaking anything—that’s the magic of digital twins. By harnessing real-time data from IoT sensors, these virtual environments create hyper-realistic simulations where robots can train safely.

Think of it like a video game where physics behave exactly like reality, but with zero consequences.

Imagine a risk-free digital playground where robot simulations unfold with laser-precise physics and unlimited potential.

Want to predict how a robot might handle a tricky manufacturing challenge? Digital twins let you run countless scenarios in milliseconds.

They’re like crystal balls for robotic performance, using advanced simulations to test strategies and optimize behaviors.

No more expensive prototypes or dangerous trial-and-error. Just pure, data-driven training that prepares robots for whatever the real world might throw at them.

Virtual Training Grounds for Robotic Systems

Because robots aren’t born knowing how to work, they need training wheels—and that’s where virtual playgrounds come in. Deep reinforcement learning enables robots to transform virtual training experiences into real-world adaptive intelligence.

Digital twins and simulation environments let robotic systems learn without breaking stuff in the real world. Here’s how these virtual training grounds work:

- High-fidelity physics simulations replicate complex real-world dynamics

- AI technologies optimize robotic performance through data-driven insights

- Robots test unpredictable scenarios without physical risk

- Extensive training iterations reduce development costs and time

Imagine a robot learning to navigate a warehouse or handle delicate objects—all through immersive virtual robotics training.

These digital worlds are like risk-free video games where machines can practice, fail, and improve without consequences. Who said learning can’t be a simulation?

Advanced Simulation Technologies in Robotics

If robots could talk, they’d probably complain about training—but simulation technologies are about to make their learning curve way less painful.

Digital twins in virtual environments let robots practice their moves without risking a costly faceplant. These high-tech training grounds use sensors and real-time machine learning to simulate everything from manufacturing operations to complex rescue missions.

Imagine a robot learning to navigate a disaster zone without actually risking its metal hide—that’s the magic of advanced simulation.

NVIDIA’s Isaac SIM and similar platforms create hyper-realistic physics models where robots can train, fail, and improve faster than ever before.

It’s like a video game, but instead of leveling up a character, you’re developing a machine that could save lives or revolutionize industries.

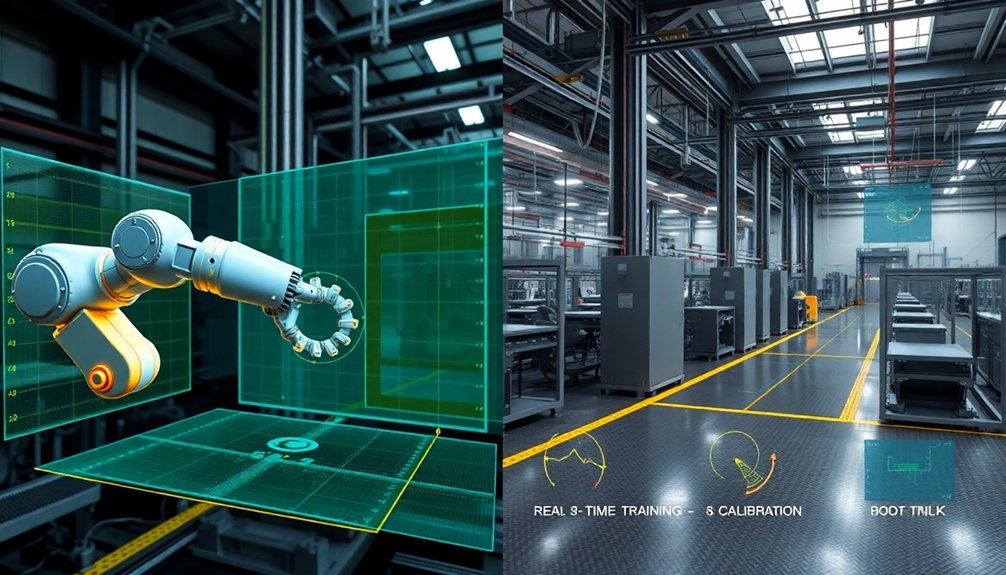

Real-Time Data and Machine Learning Integration

Robots aren’t just metal mannequins anymore—they’re learning machines that get smarter with every byte of data. Digital twins transform robotic training through powerful real-time data and machine learning integrations that make virtual models come alive:

- Sensors capture continuous performance metrics, feeding machine learning algorithms that predict potential equipment failures.

- Virtual environments simulate complex scenarios, allowing robots to train without real-world risks.

- Operational efficiency increases as digital twins adapt and refine training strategies dynamically.

- Predictive maintenance becomes smarter, identifying potential issues before they disrupt production.

Imagine a robot learning from its digital shadow, constantly evolving through data-driven insights. Humanoid robot perception draws from advanced sensor technologies that transform digital twins into increasingly sophisticated learning platforms.

Robots dance with their digital echoes, transforming raw data into intelligent adaptation.

Machine learning doesn’t just improve robots—it revolutionizes how they understand and interact with complex industrial environments. Who knew metal could be so intelligent?

Benefits of Virtual Robot Training

You’ve probably wondered why robot developers aren’t constantly breaking expensive machines during training—welcome to the magic of virtual environments.

By simulating complex scenarios without risking million-dollar hardware, you can teach robots everything from warehouse logistics to lunar exploration at a fraction of traditional training costs.

Virtual training isn’t just cheaper; it’s like giving your robot an infinite playground where it can practice, fail, and learn at lightning speed, turning potential mechanical mishaps into digital lessons.

Reduced Physical Training Costs

Let’s be real: training robots used to cost a fortune. Now, digital twins in virtual environments are slashing those expenses. Reduced physical training costs mean you’re no longer burning cash on endless hardware prototypes.

Check out how virtual robot training saves your wallet:

- Eliminates expensive physical setups

- Simulates complex scenarios without risking real equipment

- Accelerates development through rapid iteration

- Predicts robot performance using sensor data

Manufacturing industry pros are loving this approach. Your real-world counterparts can now train robots in hyper-realistic simulations without breaking the bank.

Why spend thousands on physical testing when a digital playground does the job faster, cheaper, and with zero risk?

Virtual training isn’t just smart—it’s revolutionary.

Accelerated Learning Performance

When traditional training methods hit a snail’s pace, virtual environments turbocharge robot learning like a nitrous boost in a high-performance engine.

Digital twins transform how robots prep for real-world challenges, letting them practice complex tasks without risking expensive hardware. Imagine your robotic buddy running a thousand simulations before stepping into actual terrain—that’s the magic of virtual training.

These smart platforms leverage AI and physics simulations to accelerate performance dramatically. Robots can crash, fail, and learn at lightning speed without consequences.

Want precision? Virtual worlds deliver surgical-level accuracy through repeated trials. The result? Robots that adapt faster, think smarter, and execute tasks with mind-blowing efficiency.

Who knew pixels could be the ultimate training ground for mechanical marvels?

Industries Leveraging Digital Twin Technology

You might think digital twins are just fancy computer models, but they’re revolutionizing how manufacturers simulate and optimize industrial design.

By creating virtual replicas of machines and production lines, companies can test scenarios, predict potential failures, and streamline workflows without risking real-world resources.

Imagine running a factory where every machine has a digital clone that can predict maintenance needs and optimize performance—that’s not sci-fi, that’s today’s industrial reality.

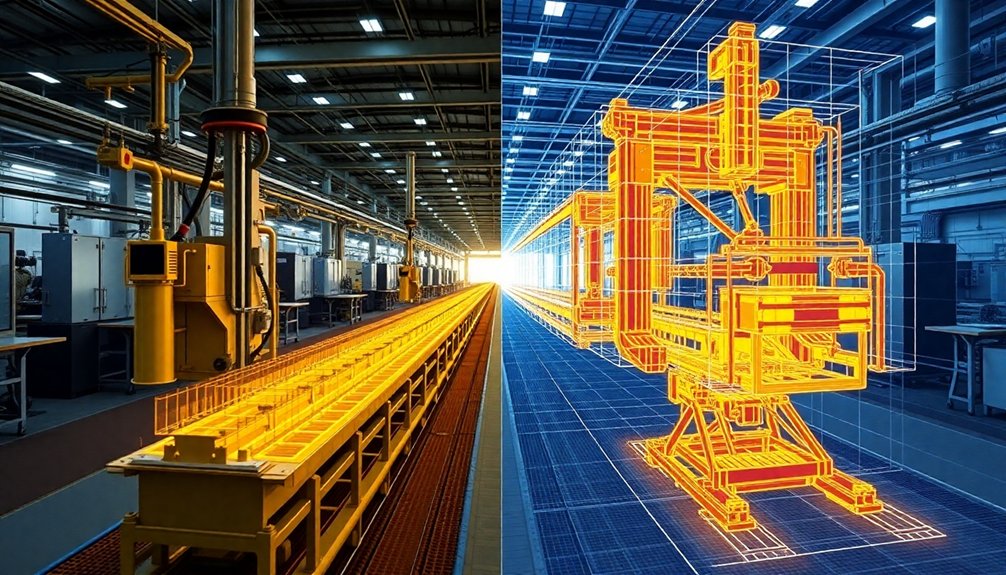

Manufacturing Digital Simulation

Digital twin technology has transformed manufacturing from a guessing game into a precision-driven science. By creating virtual models of production systems, manufacturers now wield powerful digital twins that:

- Enable real-time monitoring of complex machinery

- Predict potential equipment failures before they happen

- Simulate robotic processes in risk-free environments

- Optimize production workflows with generative AI insights

Imagine watching your factory’s entire operations unfold in a hyper-realistic digital playground before spending a single dollar on physical implementation.

Predictive maintenance isn’t just a buzzword—it’s a game-changer that saves companies serious cash. With platforms like Siemens’ Tecnomatix and NVIDIA’s Isaac SIM, manufacturers can now stress-test their systems, train robots, and identify potential hiccups without breaking a sweat or risking expensive equipment.

Who said manufacturing can’t be as cool as a sci-fi movie?

Industrial Design Optimization

Because industrial design has always been a high-stakes game of educated guesswork, digital twin technology is rewriting the rulebook for how companies prototype, test, and perfect their products.

Digital twins transform physical objects into virtual models that mirror real-world performance with uncanny precision. By capturing data from sensors and leveraging AI technologies, manufacturers can simulate complex production systems before spending millions on actual prototypes.

Imagine training a robot or designing a car without risking a single physical resource—that’s the magic of digital twins. They’re like a sandbox where engineers can experiment, predict failures, and optimize designs with near-prophetic accuracy.

The result? Faster innovation, reduced costs, and products that are smarter right out of the gate. Who wouldn’t want that competitive edge?

Future Potential of Digital Twin Simulations

As robotics barrel toward a more intelligent future, digital twin simulations are poised to become the ultimate training ground for machines that’ll reshape how we solve complex problems.

These virtual environments are revolutionizing robotic training by offering unprecedented opportunities:

- Hyper-realistic AI-powered simulations that predict robot behaviors before real-world deployment

- Predictive maintenance strategies that anticipate mechanical failures weeks or months in advance

- Rapid learning cycles enabling robots to master complex tasks in fraction of traditional training time

- Risk-free experimentation where digital twins can crash, fail, and learn without costly physical consequences

People Also Ask About Robots

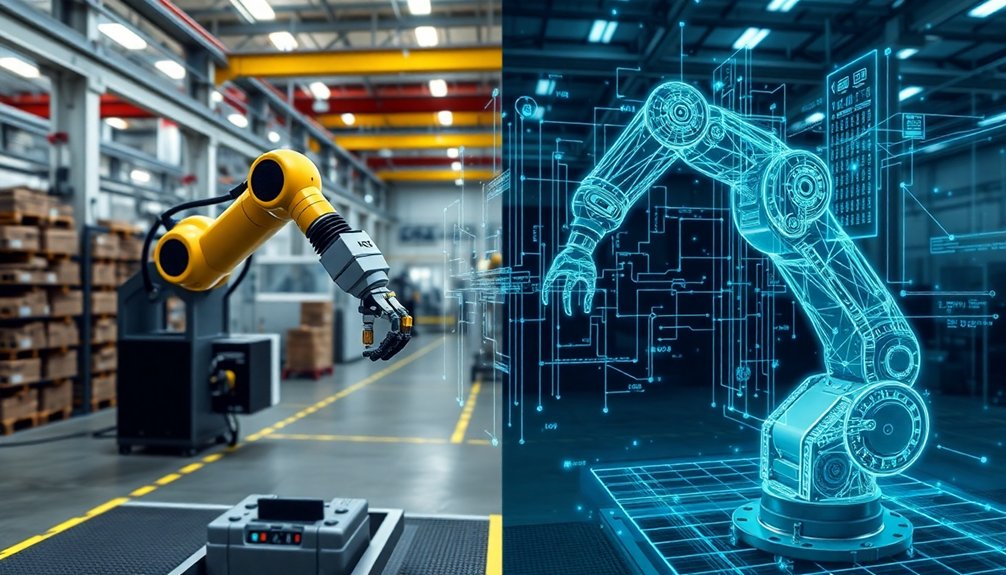

What Is a Digital Twin in Robotics?

You’ll create a virtual clone of a physical robot that mimics its exact components and behaviors, allowing safe, precise training and testing in simulated environments before real-world deployment, optimizing performance and reducing risks.

What Is the Difference Between Virtual Twin and Digital Twin?

You’ll find virtual twins focus on immersive experiences, while digital twins mirror real-world systems using live data. They’re similar, but digital twins analyze performance and optimize operations, whereas virtual twins prioritize interactive exploration.

What Is the Idea of Digital Twins?

You’ll be blown away by digital twins! They’re virtual replicas that mirror real-world objects, capturing their entire lifecycle through continuous data updates, enabling predictive insights, performance optimization, and smarter decision-making across various industries.

What Is a Digital Twin With an Example?

A digital twin’s your virtual replica of a physical object, like a factory machine. You’ll see its real-time performance, simulate its behavior, and predict maintenance needs before actual problems occur.

Why This Matters in Robotics

Digital twins are changing the game. You’ll soon see robots learning complex tasks in virtual worlds before stepping into reality. It’s like giving machines a “dress rehearsal” before the big performance. Machine learning and real-time data are supercharging these simulations, transforming how industries train and deploy robotic systems. The future isn’t just coming—it’s already practicing in pixels, getting smarter with every virtual iteration.