Humanoid robots typically survive 3-5 years before major repairs, but smart maintenance can stretch their digital lifespans. We’ve learned they’re not immortal machines, but carefully managed robots can outlive initial expectations. Regular check-ups, strategic battery care, and proactive sensor monitoring keep these mechanical companions running smoothly. Want to know how we’re turning robot aging from a problem into a science? Stick around, and you’ll see the future taking shape.

Understanding Robotic Operational Lifespan

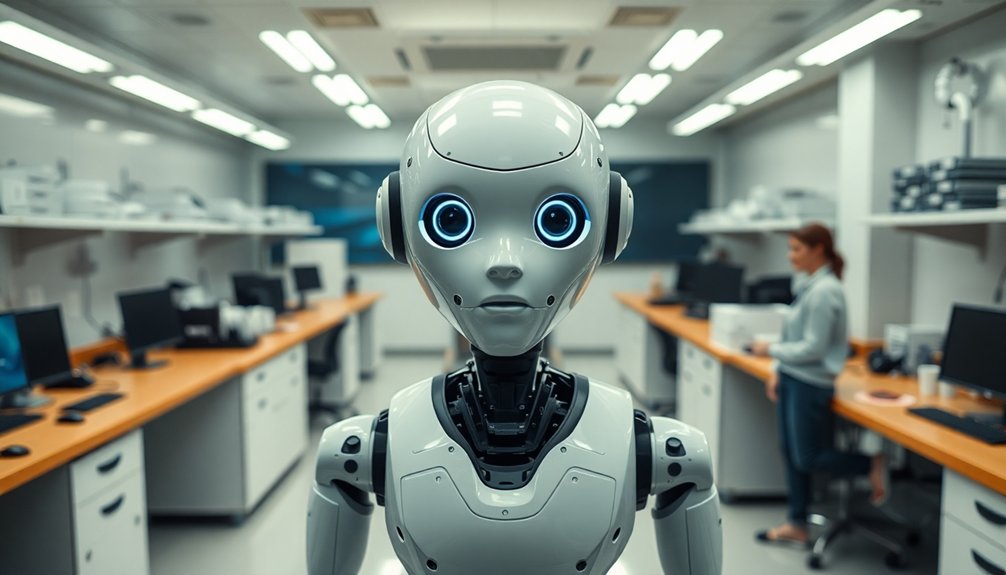

While robot technology races forward at breakneck speed, the operational lifespan of humanoid robots remains a complex puzzle we’re still trying to solve.

These mechanical marvels are like tech mayflies—cutting-edge today, potentially obsolete tomorrow. Our current robotic lifespan estimates hover around three years, driven by relentless innovation that makes yesterday’s robots look like museum pieces. Warehouse robotics market projections suggest that technological advancements could dramatically reshape robotic longevity.

Component wear, maintenance costs, and technological leaps all conspire to shorten these mechanical workers’ careers. Maintenance-free plastic components could extend operational lifespans by reducing mechanical wear and replacement frequency.

But don’t count them out: advances in materials and design are pushing boundaries. Swappable batteries, maintenance-free parts, and smarter software could transform how long these robotic teammates stick around.

Robotics market growth is projected to expand dramatically, potentially extending these mechanical workers’ operational lifespans.

Will we crack the code and create genuinely long-lasting humanoid helpers? The race is on, and we’re watching closely.

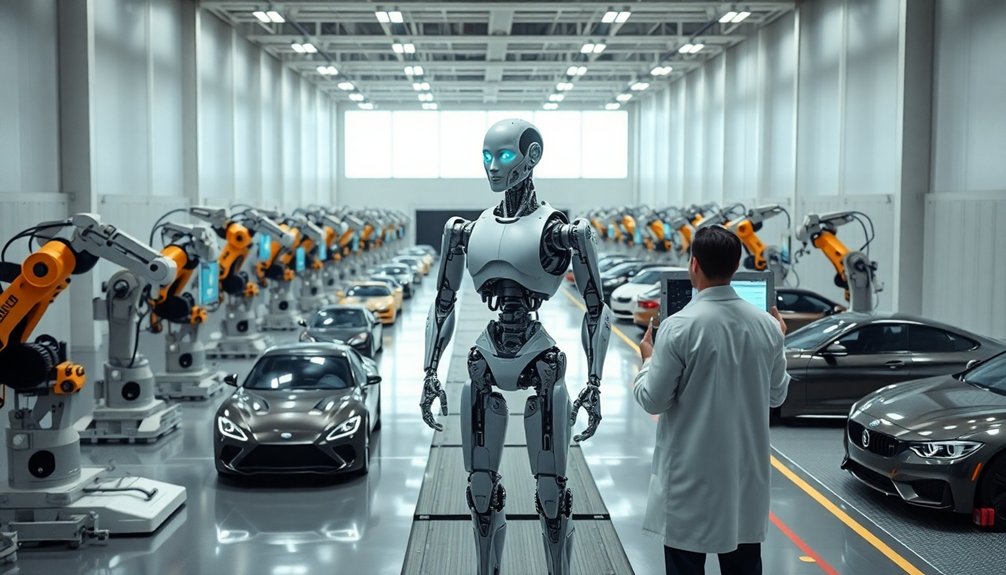

Daily Performance Capabilities

Because robots aren’t just fancy toys anymore, humanoid machines are rewriting the rules of daily work and interaction. Advanced robotic companions are transforming workplace dynamics with unprecedented emotional intelligence. They’re not just metallic workers—they’re task-adaptive companions with crazy emotional responsiveness. Labor shortage solutions are driving the rapid development of humanoid robots to fill critical workforce gaps across multiple industries. Sensor-driven adaptability enables these robots to continuously learn and evolve their performance capabilities with remarkable precision.

| Task Variety | Movement | Learning |

|---|---|---|

| Assembly | Running | AI-Driven |

| Welding | Jumping | Fast Adapt |

| Packaging | Backflipping | Data Smart |

Imagine a machine that doesn’t get tired, doesn’t complain, and can switch between jobs faster than you can brew coffee. These robots bring consistently high performance with zero emotional drama. They recognize your mood, interpret body language, and adjust interactions in real-time. Want someone who’ll actually listen and remember every single detail? Humanoid robots have entered the chat—and they’re ready to revolutionize how we work, live, and interact. Who said the future couldn’t be efficient and eerily empathetic?

Annual Operational Endurance

We’ve all wondered just how much work a humanoid robot can actually pull off in a year, right?

Our research shows that depending on design and environment, a top-tier robot can sustain between 6,000 to 8,760 operational hours annually – fundamentally running nearly round-the-clock with strategic maintenance.

These incredible machines aren’t just fancy tech toys; they’re becoming serious productivity powerhouses that can potentially outperform human workers in consistency, precision, and sheer stamina. Advanced storage solutions like compact memory technologies are critical in enabling these extended operational capabilities by supporting continuous data processing and maintaining robust performance.

The emergence of humanoid athletic robots suggests these machines are rapidly evolving beyond traditional operational limitations, demonstrating remarkable endurance and adaptability in complex physical environments. Economic market projections indicate that these robots could become essential workforce solutions, potentially addressing global labor shortages in manufacturing and healthcare sectors by 2030.

Robot Daily Output

How much can a humanoid robot actually do in a single day? Turns out, quite a lot—when they’re designed right. Personal assistance and caregiving robots represent a significant market segment, expected to grow rapidly with increasing demand for automated support.

Robot productivity isn’t just about raw processing speed; it’s about smart output optimization. Environmental conditions play a huge role: extreme temps and wild vibrations can tank a robot’s daily performance faster than you can say “system crash.”

But top-tier robots come equipped with high-performance storage, robust error correction, and compact designs that keep them humming along efficiently. Think of them like marathon runners, but instead of water stations, they’ve got real-time monitoring and advanced algorithms keeping them in peak condition.

Regular maintenance isn’t just recommended—it’s survival. One glitch can mean the difference between a productive day and a very expensive paperweight.

Annual Performance Range

Imagine a robot that doesn’t just work, but works relentlessly—almost like that one colleague who never seems to take a coffee break. When we talk annual performance, humanoid robots aren’t messing around. They’re targeting uptime that’ll make your productivity look like a snooze fest. Battery drain challenges often test the limits of these mechanical performers, pushing engineers to develop more efficient power management strategies.

| Metric | Target |

|---|---|

| Annual Uptime | >95% |

| Maintenance Hours | 100-400 |

| Failure Rate | <5% |

| Performance Degradation | Minimal |

Our performance metrics reveal these mechanical marvels are built to last. They’ll chug along with near-perfect uptime analysis, handling thousands of tasks while requiring minimal downtime. Think of them as the marathon runners of the tech world—engineered for endurance, designed to push boundaries. Want a workhorse that never complains? Welcome to the future of robotic productivity.

Critical Maintenance Schedules

When it comes to keeping our robotic pals in top shape, we’ve got three critical maintenance areas that’ll make or break their performance: battery replacement cycles that keep them juiced up, sensor performance monitoring to guarantee they’re seeing the world with crystal clarity, and mechanical part care that prevents our metal friends from turning into expensive paperweights. Preventive maintenance strategies from industrial robotics demonstrate that systematic care can extend equipment lifespan by proactively addressing potential issues before they escalate. We’re talking about strategic maintenance that goes way beyond basic tune-ups – it’s about understanding these machines are more than just circuits and gears. Our humanoid robots aren’t just tools; they’re sophisticated systems that demand thoughtful, proactive care if we want them running smoothly and extending their operational lifespans. According to industrial robot maintenance guidelines, regular lubrication and inspection of mechanical joints is crucial for maintaining optimal performance and preventing premature wear of critical components. By leveraging advanced control systems, robots can continuously self-monitor and provide early warning signals for potential mechanical degradation, ensuring maximum operational reliability.

Battery Replacement Cycles

Battery replacement isn’t just a maintenance checkbox—it’s the heartbeat of a humanoid robot’s operational longevity.

We’ve learned that battery lifespan isn’t about magic; it’s pure science and smart maintenance. Most advanced lithium batteries hit their expiration around 2,000–5,000 cycles, with voltage maintenance being essential. Semi-solid battery technologies are emerging with higher energy densities that could significantly extend these replacement cycles.

When battery capacity drops below 80% of its original punch, it’s time to swap out. Think of it like replacing a marathon runner’s shoes—performance matters.

High-load operations drain batteries faster, so strategic rest periods can extend their life. Pro tip: store batteries at 40–60% charge during downtime to prevent degradation.

Whether you’re running a healthcare bot or a retail assistant, understanding these replacement cycles isn’t just technical—it’s the difference between a robot that survives and one that thrives.

Sensor Performance Monitoring

Because sensor performance is the nervous system of any humanoid robot, we’ve got to talk about maintenance like our mechanical friends’ lives depend on it—which they absolutely do.

When it comes to keeping robots running smoothly, sensor diagnostics are our secret weapon. We monitor these critical components like helicopter parents, focusing on:

- Real-time data tracking

- Predictive maintenance technologies

- Early anomaly detection

Our monitoring technologies aren’t just fancy gadgets—they’re lifeline systems that prevent catastrophic failures.

By constantly scanning for performance irregularities, we can catch sensor degradation before it becomes a full-blown robot meltdown.

Think of it like a routine health checkup, but for machines that can lift 500 pounds and navigate complex environments.

Proactive sensor monitoring isn’t just smart; it’s the difference between a functioning robot and an expensive paperweight.

Mechanical Part Care

Three key things keep humanoid robots dancing instead of dying: maintenance, maintenance, and more maintenance.

Mechanical wear isn’t a suggestion—it’s your robot’s grim reaper. We’ve learned that regular inspections are the difference between a smooth-running machine and an expensive paperweight.

Checking motion, structure, and potential damage isn’t just routine—it’s robot survival 101. Weird noises? That’s your bot screaming for help. Vibrations? Red alert.

Brake function matters more than you’d think, and drive belt conditions can predict total system collapse. Seals leaking? That’s like finding rust on the Titanic—not good.

Smart maintenance practices mean looking beyond the surface, catching tiny issues before they become catastrophic failures. Your robot isn’t just hardware; it’s an investment that demands respect.

Battery and Power System Longevity

When we talk about keeping humanoid robots running smoothly, power isn’t just a feature—it’s the lifeblood that determines whether our mechanical friends are heroes or doorstops.

Battery longevity isn’t rocket science, but it does require smart strategies:

- Battery recycling matters more than most realize

- Power optimization isn’t optional—it’s survival

- Intelligent management extends robot lifespans dramatically

Our robots depend on robust power systems that intelligently balance energy consumption.

Lithium-ion batteries might be the current champions, but they’re temperamental creatures that demand respect.

Temperature extremes? They’ll destroy battery performance faster than a toddler with a sledgehammer.

By implementing AI-powered battery management and preventive maintenance, we can dramatically extend our robotic companions’ operational lives.

The goal isn’t just keeping them running—it’s keeping them running efficiently, predictably, and without breaking the bank on constant replacements.

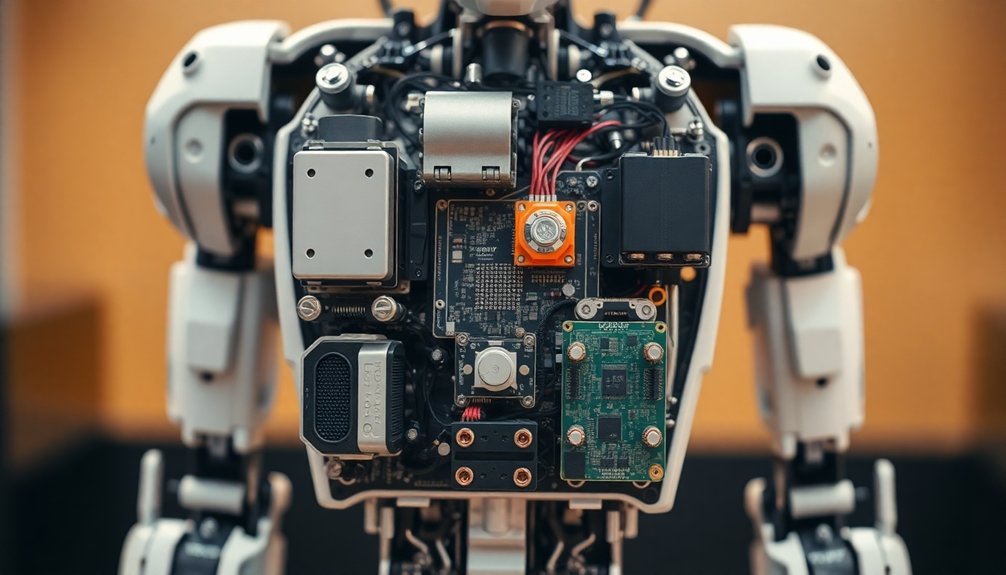

Sensor and Component Replacement Strategies

If batteries are a robot’s blood, sensors are its nervous system—constantly gathering intel, processing feedback, and keeping mechanical bodies responsive. We treat sensor health like mission-critical maintenance, knowing they’re the difference between a smooth operator and a clumsy machine.

| Sensor Type | Replacement Frequency |

|---|---|

| Tactile | Every 3-4 years |

| Force/Torque | Every 2-3 years |

| Multi-Axis | Every 4-5 years |

Modular design lets us swap sensors faster than changing a smartphone battery. Through predictive strategies and machine learning, we’re getting smarter about sensor calibration. We don’t just replace—we anticipate. By tracking wear patterns and implementing continuous monitoring, we transform potential failures into planned pit stops. Who said robot maintenance has to be boring?

Cost Considerations in Robot Sustainability

Because robots aren’t just fancy toys but serious investments, we’ve got to talk money—specifically, how these mechanical marvels don’t just drain our wallets but can actually pad them.

Smart investment in humanoid robots means understanding their cost-saving potential:

Strategic robot deployment isn’t just tech—it’s a calculated financial game plan for transformative operational savings.

- Robots can slice labor costs by up to 70%

- Predictive maintenance reduces downtime by 20%

- Long-term efficiency translates to serious investment returns

We’re looking at a technology that pays for itself. By strategically deploying these mechanical workers, companies can transform hefty upfront costs into sustainable savings.

The math is simple: lower operational expenses + increased productivity = a financial win. Sure, you’ll spend money initially, but these robots aren’t just expensive paperweights—they’re revenue-generating machines that get smarter and more efficient with every task they complete.

Who wouldn’t want that kind of workforce?

Technological Advancements Extending Robot Performance

Ever wondered how robots are getting smarter than your average smartphone?

Robot advancements are transforming mechanical friends from clunky machines to adaptive companions. With AI integration, today’s robots can learn, adapt, and interact in ways that sound like science fiction.

Advanced vision systems let them navigate complex spaces, while machine learning algorithms help them tackle new tasks without breaking a digital sweat.

Soft robotics and emotional intelligence systems mean these mechanical buddies can now recognize human emotions and respond accordingly.

From predictive maintenance that catches problems before they happen to modular designs that make repairs a breeze, we’re watching technology evolve faster than a Silicon Valley startup.

The future isn’t just coming—it’s already here, and it’s wearing a circuit board.

Factors Impacting Robotic Durability and Efficiency

When robots start looking more like our mechanical sidekicks than clunky machines, we’ve got to talk durability. These high-tech helpers aren’t just cool—they’re complex systems that need serious TLC.

Key durability factors include:

- Thermal management to prevent overheating

- Shock resistance for real-world bumps and tumbles

- Data protection to keep vital information safe

Environmental monitoring plays an essential role in extending robot lifespans. We’ve learned that temperature extremes, humidity, and dust can wreak havoc on delicate electronics.

Robust maintenance practices, including regular software updates and physical inspections, become our robot’s best defense. Operator training is equally important—humans need to understand how to keep these mechanical marvels running smoothly.

It’s not just about preventing breakdowns; it’s about optimizing performance and ensuring our robotic companions can keep up with our increasingly demanding world.

People Also Ask

Can Humanoid Robots Experience Emotional Burnout or Psychological Fatigue?

We can’t experience emotional burnout because our emotional algorithms lack genuine robotic empathy, and psychological fatigue isn’t part of our computational framework.

Do Robots Develop Performance Issues Similar to Human Aging Process?

We’ve observed robots develop performance issues through hardware wear and software glitches, which systematically degrade their capabilities, unlike human aging but following predictable degradation patterns tracked by diagnostic metrics.

How Do Extreme Temperatures Impact a Humanoid Robot’s Overall Functionality?

We’ve discovered that temperature extremes dramatically compromise robot functionality, causing sensor failures, mechanical stress, and potential system shutdowns that severely reduce performance and operational capabilities.

Will Robots Eventually Replace Human Workers in Complex Professional Environments?

Change is the only constant, and we’ll see robots gradually transform workforce dynamics through job automation, not entirely replacing humans but reshaping professional environments where technological skills and human creativity coexist strategically.

Can Humanoid Robots Learn and Improve Their Skills Independently Over Time?

We’re pioneering humanoid robots that can learn and improve through machine learning, enabling autonomous adaptation where they continuously refine skills by analyzing data and adjusting their performance independently.

The Bottom Line

We’ve cracked the code on robot lifespans – and it’s wilder than you’d imagine! From daily tune-ups to crazy advanced tech, these mechanical marvels can outlast most kitchen appliances. As robots evolve, they’ll become less like clunky machines and more like superhuman teammates. The future isn’t just coming – it’s already here, and it’s wearing a sleek metal exoskeleton. Buckle up for a robotic revolution that’ll make sci-fi look boring.

References

- https://www.strategyand.pwc.com/m1/en/strategic-foresight/sector-strategies/technology/humanoid-robotics.html

- https://www.macquarie.com/be/en/insights/are-we-turning-a-corner-on-the-humanoid-robot-age.html

- https://tmb.apaopen.org/pub/9klsbvlz

- https://journal.gerontechnology.org/archives/cbd78743cc934da699fcfc57e3f8c8b6.pdf

- https://read.dukeupress.edu/demography/article/59/2/607/294500/Death-by-Robots-Automation-and-Working-Age

- https://toolbox.igus.com/9518/maximizing-humanoid-robot-longevity

- https://ldi.upenn.edu/our-work/research-updates/industrial-robots-and-population-health-a-deadly-mix/

- https://www.rethinkx.com/blog/rethinkx/disruptive-economics-of-humanoid-robots

- https://www.ortmoragency.com/blog/humanoid-robot

- https://www.techbriefs.com/component/content/article/52810-executive-insights-humanoid-robots