Robotic joints now move like human muscles by blending living cells with electrical zaps. You’ll see muscle fibers grown on tiny scaffolds that contract when shocked, mimicking your body’s own movements. Imagine tiny, lab-grown muscles powered by precise electrical pulses, turning stiff robots into fluid, almost-alive machines. Weird? Totally. Revolutionary? Absolutely. Want to know how scientists are basically creating cyborg muscles that could redefine human-machine interaction?

The Science of Biohybrid Muscle Movement

While traditional robots have always seemed more “clank” than “flex,” biohybrid muscle movement is flipping the script on robotic engineering.

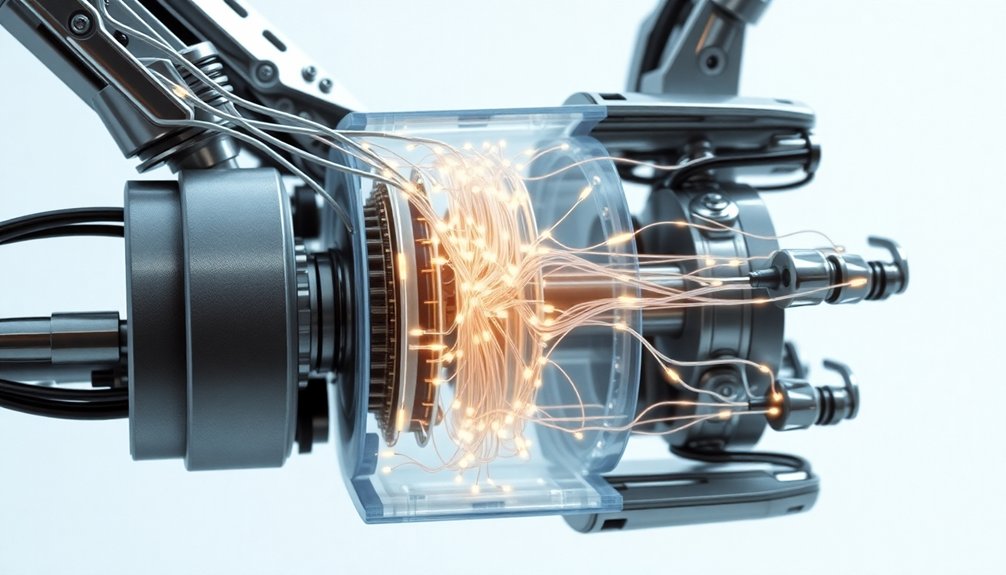

Imagine a human arm that moves with the organic grace of actual muscle, not just mechanical rotational or linear joints. Scientists are growing muscle cells in hydrogel scaffolds that contract when zapped with electricity, creating robotic movements that feel almost alive.

Robotic limbs dance with living muscle, electrified hydrogel scaffolds breathing organic motion into mechanical dreams.

These lab-grown muscles can bend, stretch, and respond like the real deal, but with a sci-fi twist. The magic happens when myoblasts are carefully cultivated to form muscle fibers that mimic human tissue.

Sure, the current tech isn’t perfect—muscle cells only survive a few days, and precision is still a work in progress. But we’re watching the future of robotics unfold, one muscle fiber at a time.

Cultivating Living Muscle Cells for Robotic Joints

From robotic arms that twitch like half-asleep insects to muscle tissues grown in lab petri dishes, the journey of creating living robotic joints is anything but predictable.

You’re watching scientists cultivate myoblasts on hydrogel scaffolds, coaxing them into aligned muscle fibers that’ll eventually flex and contract. By zapping these cellular constructs with electrical pulses, researchers transform delicate cell clusters into responsive robotic muscles that mimic human movement.

But here’s the catch: these living tissues aren’t immortal. They’ll die after a few days, making each robotic joint a temporary marvel of biological engineering.

Think of them as muscle mayflies—brief, beautiful, and utterly fascinating. The goal? Create joints that move with human-like precision, bridging the gap between cold machinery and warm, pulsing life.

Electrical Stimulation and Muscle Fiber Contraction

Because nerves don’t come standard in robotic limbs, scientists have found a shocking workaround: electrical stimulation.

They’re basically hacking muscle movement by zapping specially grown muscle cells with precisely timed electrical impulses. Think of it like jumpstarting a car, but for robot muscles.

Imagine creating tiny muscle fibers in a lab, then making them dance to an electrical rhythm. These microscopic performers contract just like human muscles when stimulated, generating movement that’s surprisingly organic.

Soft robotic actuators are pioneering techniques that mimic human muscle movement with unprecedented precision, bridging the gap between mechanical and biological motion.

It’s not perfect yet—complex movements still challenge researchers—but the potential is mind-blowing. You’re looking at the future where robots might move with a fluidity that rivals biological creatures.

The catch? Right now, we’re still in the “cool experiment” phase, not the “fully functional cyborg” stage.

Challenges in Developing Biohybrid Robotic Systems

You’ve probably wondered why your sci-fi robot dreams keep hitting roadblocks: muscle tissue in biohybrid systems dies faster than a mayfly at a tech conference.

Electrical stimulation currently sucks at precise muscle control, making your robotic joint movements look more like a drunk dancer than a smooth machine.

The core problem? Muscle fibers break down under friction and stress, turning your cutting-edge robotic prototype into an expensive pile of organic goo.

Muscle Tissue Degradation

When muscle tissue starts breaking down faster than a cheap smartphone battery, biohybrid robotics hits a major roadblock. Your lab-grown muscles are like temporary house guests—they arrive with excitement but vanish before you’re ready.

The problem? These tissue constructs struggle with self-maintenance due to critical limitations:

- No fluid exchange system means muscles can’t repair themselves like natural tissue

- Constant friction during movement accelerates breakdown, even with biocompatible lubricants

- Electrical stimulation lacks precision, making fine motor control about as reliable as a drunk GPS

Imagine building a robot that falls apart after a week. Not exactly the sci-fi dream, right?

Scientists are racing to solve these degradation challenges, knowing that sustainable muscle tissue could revolutionize everything from prosthetics to tiny medical robots.

But for now, it’s a frustrating game of biological Jenga.

Electrical Control Precision

If electrical control were a musical instrument, current biohybrid robotic systems would be playing a kazoo while trying to perform a Mozart symphony.

Mimicking human muscle movements isn’t just hard—it’s practically impossible with today’s tech. You’re dealing with a precision problem that makes brain surgery look like child’s play. Current stimulation methods are about as nuanced as a sledgehammer trying to paint a watercolor.

The fundamental challenge? Replicating the jaw-dropping complexity of human nervous system control. These robotic joints can contract, sure, but they’re more like clumsy marionettes than fluid, responsive muscle groups.

Researchers are frantically trying to bridge the gap between basic electrical stimulation and the intricate neural signaling that lets humans perform everything from brain surgery to playing jazz piano. The quest continues.

Advanced robotic control systems leverage sensor fusion and machine learning techniques to incrementally improve the precision of biomechanical movement simulation.

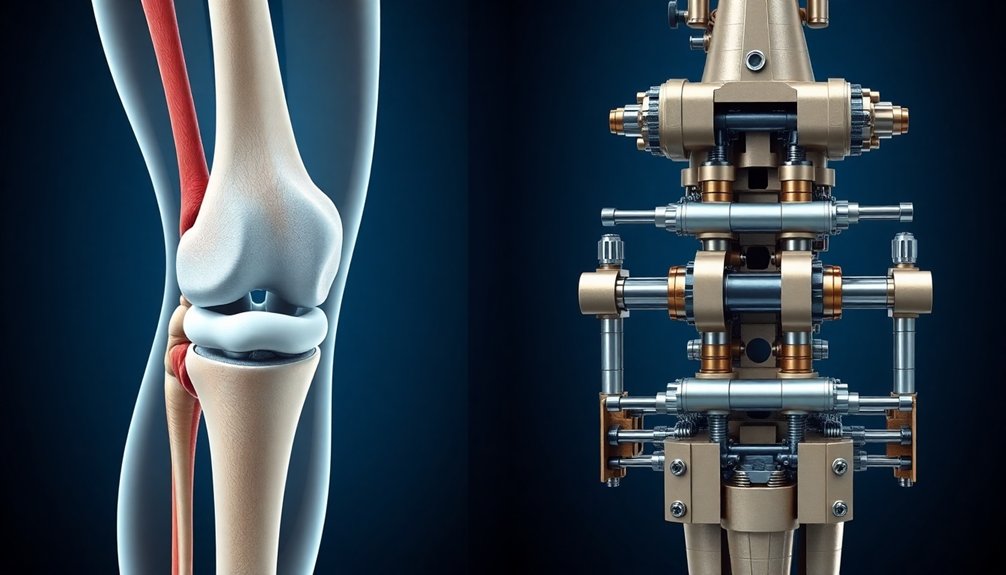

Comparing Biological and Mechanical Joint Mechanisms

You’ve probably never thought about how your muscles move compared to a robot’s joints, but it’s weirdly fascinating.

While your muscles contract and slide like microscopic pulleys, robotic joints rely on precision motors that can mimic—but never quite perfectly replicate—biological movement.

Think of it like comparing a master musician’s improvised performance to a perfectly programmed player piano: similar in mechanics, but wildly different in soul and spontaneity. Servo-powered muscles like those in advanced humanoid robots use planetary gears to replicate human joint mechanics with remarkable precision.

Muscle Contraction Mechanisms

Because muscle movement is the beating heart of both biological and mechanical systems, understanding how joints actually work becomes a fascinating journey of comparison.

You’ll find that muscle contraction isn’t just about moving parts—it’s about intelligent design.

Consider these key mechanisms:

- Signal processing: Biological systems use nerve impulses, while robotic joints rely on electrical control signals.

- Energy conversion: Human muscles burn ATP; robots convert electrical energy into mechanical motion.

- Movement generation: Biological muscles slide filaments; robotic joints use precise motor rotations.

Think of it like comparing a jazz musician’s spontaneous performance to a perfectly programmed synthesizer.

Both create music, but through radically different techniques.

The magic isn’t in the mechanism, but in how each system transforms potential into kinetic energy—turning potential movement into actual, purposeful motion. Sophisticated control systems enable humanoid robots to mimic complex biomechanical patterns with remarkable precision.

Joint Movement Similarities

When you dig beneath the surface of movement, biological and mechanical joints start looking more like distant cousins than complete strangers.

Your body’s pivot points and robotic joints share a secret handshake of motion—both rely on strategic turning points that reveal incredible flexibility. Think of a robot’s articulated arm like your own skeletal structure: each joint becomes a calculated opportunity for reaching, twisting, and positioning.

While your muscles get neural signals, robots use advanced algorithms that map out precise movements with mathematical precision. Proprioceptive sensors provide additional feedback that helps robots understand their body positioning and refine movement capabilities.

The big difference? Robots don’t get tired or complain about doing repetitive tasks. They’re fundamentally the ultimate worker, mimicking human mobility with cold, calculated efficiency.

Who knew machines could be such impressive copycats of biological engineering?

Mechanical Design Adaptations

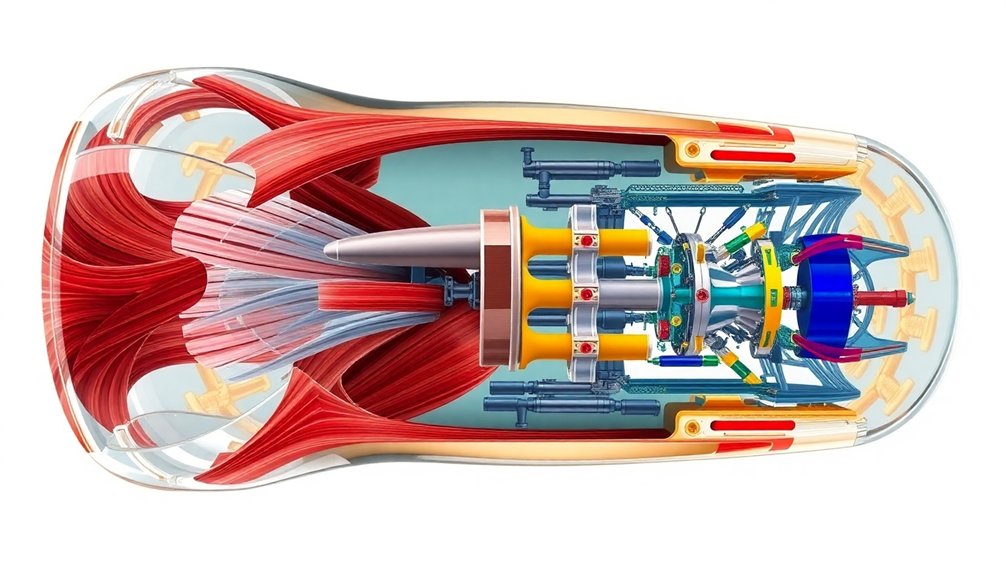

Imagine robotic joints as mechanical chameleons, constantly adapting their design to mirror the breathtaking complexity of biological movement. They’re not just metal and gears, but sophisticated mimics of human anatomy.

These joints evolve through clever engineering tricks:

- Pivot points that replicate ligament flexibility, allowing robots to twist and bend like gymnasts.

- Torque sensors that capture muscle-like feedback, transforming rigid mechanics into responsive motion.

- Pneumatic systems that simulate fluid muscle contractions, giving robots strength without bulk.

Think of it like building a transformer that moves with organic grace. Your robotic arm isn’t just programmed—it’s engineered to feel.

Pneumatic pressures push and pull, encoders track micro-movements, and suddenly you’ve got a machine that doesn’t just move, but moves with intention.

Neural network algorithms enable advanced robots to analyze and optimize movement strategies, pushing the boundaries of mechanical mobility even further.

Pretty wild, right? Welcome to the future of mechanical mobility.

Potential Applications in Robotics and Medical Technology

Imagine prosthetics that move like real muscles, adapting seamlessly to your body’s unique contours. Soft robotics aren’t just cool tech—they’re game-changers for patients with motor impairments. These biohybrid joints can help stroke survivors regain movement or support athletes recovering from injuries. Tactile sensors enable robots to interpret touch and movement with unprecedented precision, enhancing the biomechanical accuracy of prosthetic limbs.

Think of robotic joints as your body’s high-tech understudy. They calculate precise angles and movements, mimicking human muscle flexibility with algorithms that would make a mathematician swoon.

Whether it’s a delicate surgical assistant or a rehabilitation companion, these joints are rewriting what’s possible in medical technology. Who knew robots could be so… human?

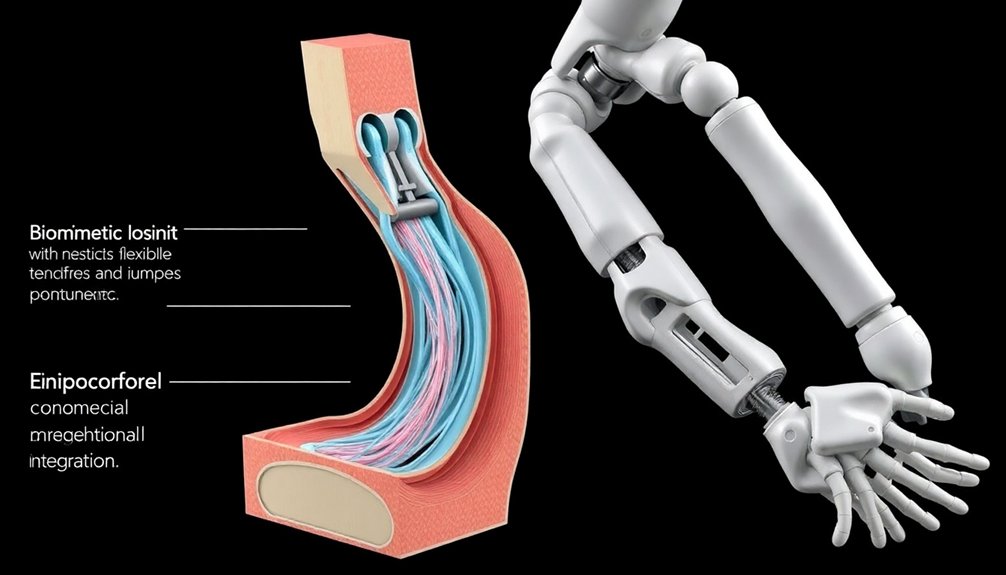

Advancing Soft Robotics Through Biological Integration

The robots of tomorrow won’t just move—they’ll breathe and flex like living creatures. Soft robotics is revolutionizing how machines mimic human motion by integrating biological muscle tissue directly into robotic joints.

Consider these cutting-edge developments:

- Myoblasts cultured in hydrogel scaffolds create muscle fibers that contract electrically, mimicking natural muscle function.

- Biocompatible lubricants prevent tissue breakdown during continuous movement.

- Biohybrid designs enable more nuanced, adaptive motion compared to traditional rigid robotic systems.

Imagine a prosthetic limb that responds as naturally as your own muscles, or a rehabilitation robot that understands precisely how human movement works.

We’re not just building machines anymore—we’re engineering living, breathing mechanical systems that blur the line between technology and biology.

Who said science fiction was just fiction?

Future Directions in Biohybrid Joint Design

When bioengineers crack the code of truly dynamic biohybrid joints, we’ll witness a robotic revolution that makes today’s machines look like clunky toys.

Imagine joints that heal themselves, contract with surgical precision, and move almost indistinguishably from human muscles.

You’re looking at a future where hydrogels and electrical stimulation transform robotics from rigid metal contraptions into living, breathing mechanisms.

These next-gen joints won’t just mimic movement—they’ll anticipate it, responding with the fluid grace of a professional dancer.

By integrating live muscle tissue with smart sensors, researchers are building robots that could redefine rehabilitation, prosthetics, and human-machine interaction.

Who knows? Your future bionic companion might just move more naturally than you do.

People Also Ask About Robots

How Do Robots Move Like Humans?

You’ll hit the nail on the head when you understand robots move by mimicking human muscle mechanics through advanced actuators, kinematics algorithms, and integrated sensors that coordinate precise, fluid joint movements.

How Do Robotic Joints Work?

You’ll find robotic joints move through electric motors, pneumatic cylinders, or hydraulic systems, acting like muscles by pivoting, rotating, and flexing to generate precise mechanical motion across multiple directional planes.

How Do Robotic Muscles Work?

You’ll find robotic muscles convert energy into motion using actuators like pneumatic or hydraulic systems. They’re designed to flex and contract, mimicking biological muscle movements through precise force generation and sensor-driven adjustments.

How Do Robots Move Their Limbs?

You’ll control robotic limb movement through actuators like electric motors or hydraulic systems, which generate precise motions by mimicking muscle contractions and using sophisticated kinematic algorithms to navigate complex tasks.

Why This Matters in Robotics

You’re watching biology and engineering dance together, turning robots from clunky machines into living, breathing systems. Imagine muscles grown in labs, pulsing with electrical signals, transforming mechanical joints into something almost… human. We’re not just building robots anymore; we’re growing them. And while challenges remain, the future looks like a sci-fi dream where technology doesn’t just mimic life—it becomes it.