Table of Contents

Robots are eating your job—and maybe saving your life. From car factories to operating rooms, these precision machines are reshaping how work gets done. They’re faster, smarter, and don’t complain about overtime. Manufacturing? Automated. Surgery? Robotic. The future isn’t just coming; it’s already here, turning humans into supervisors and machines into workers. Want to know how deep this rabbit hole goes?

The Industrial Revolution of Automation

When the gears of industry first started turning, nobody could’ve predicted how dramatically automation would reshape human work. Those early steam engines and textile machines weren’t just tools—they were rebellious innovators breaking traditional labor boundaries. Industrial control systems emerging in the 1930s allowed calculated responses to manufacturing disruptions, further accelerating technological transformation.

Imagine a world where a single machine could do the work of dozens of workers, faster and without complaint. From Oliver Evans’ automated flour mill to Henry Ford’s revolutionary assembly line, each innovation whispered the same promise: efficiency isn’t just possible, it’s inevitable. By the mid-20th century, the rise of industrial robotics transformed manufacturing from manual labor to precision-driven production. Warehouse robotic systems are now projected to reach a market value of $17.98 billion by 2032, demonstrating the continued evolution of automated technologies.

These technological leaps weren’t just about making things—they were about reimagining what human potential could look like. Each mechanical advancement challenged the old ways, transforming factories from human-powered spaces to algorithmic symphonies of productivity.

Think automation was just about machines? Think again.

Manufacturing’s Robotic Transformation

Robots aren’t just Hollywood sci-fi anymore—they’re reshaping manufacturing faster than you can say “assembly line 2.0”.

These mechanical workers are invading factories everywhere, turning production into a high-tech dance of precision and speed. Imagine robots collaborating seamlessly with humans, picking up complex tasks with ease and cutting down human error.

Robots: transforming factories into dynamic, error-free zones of precision and collaborative innovation.

From automotive plants to electronics workshops, they’re boosting productivity like never before. Sensor fusion techniques help robots navigate increasingly complex manufacturing environments with remarkable precision. Cobots are leading the charge, proving that machines can be safe, flexible, and surprisingly adaptable. In 2023, more than 39,000 industrial robots were installed in US manufacturing, signaling a significant technological leap.

With AI and machine learning driving their capabilities, these robots aren’t just tools—they’re intelligent partners transforming how we make things. By addressing labor supply shortages, manufacturers are finding innovative solutions to global workforce challenges.

Want to stay competitive? Better get on board or risk being left in the industrial dust.

Precision Engineering in Healthcare

Because precision matters more than ever in healthcare, engineers are transforming medical technology from a guessing game into a data-driven science. Collaborative robots are emerging as critical partners in surgical precision and patient care.

You’re witnessing a revolution where AI and software predict protein structures, analyze genetic risks, and customize treatments faster than ever before.

Imagine software that matches oncologists’ recommendations with 90% accuracy or wearable devices tracking your health in real-time.

It’s not sci-fi — it’s happening now.

Precision engineering is slashing drug development costs, preventing diseases before they strike, and turning complex medical data into actionable insights.

North America’s precision diagnostics market is projected to reach $246.66 billion by 2029, driving unprecedented medical innovation.Precision medicine software is expanding rapidly, with market value projected to reach $4.3 billion by 2032, signaling massive technological transformation.

Want personalized healthcare that understands your unique genetic blueprint?

These technologies are making it possible, one algorithm and robotic breakthrough at a time.

The future isn’t just smarter healthcare — it’s healthcare that knows you.

Surgical Innovations Through Robotics

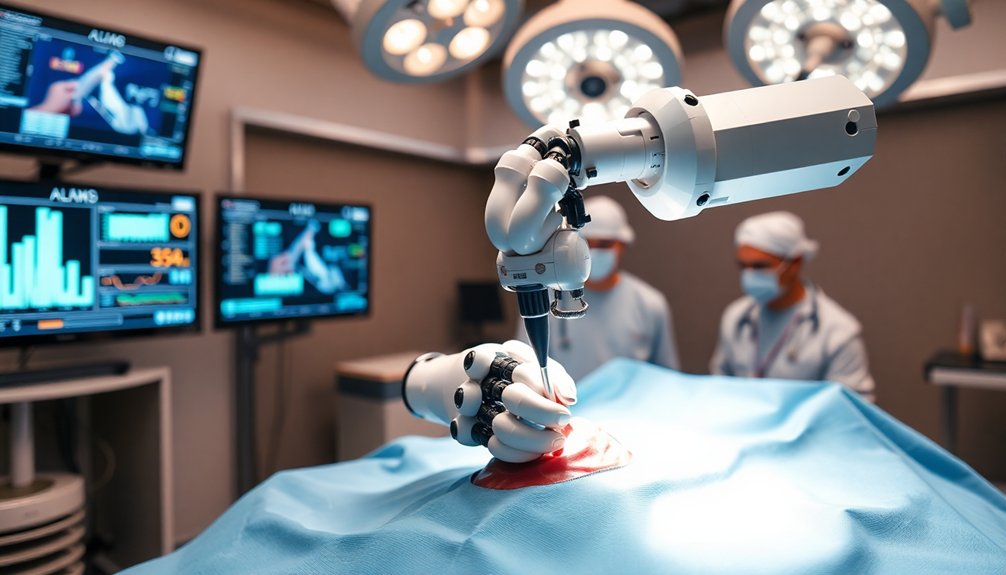

Robots have transformed surgery from a shaky-handed human art to a mechanically precise science. Remember the PUMA 560? It kicked off robotic medical magic back in 1985 with a brain biopsy that Changed. Everything.

Robotic surgery: turning medical imprecision into a digital dance of microscopic perfection.

Since then, machines like da Vinci have turned complex procedures into video game-like precision operations. Surgeons now control robotic arms that move with impossible grace, making tiny incisions most human hands couldn’t dream of achieving. Neuromorphic computing has further enhanced robotic surgical precision, enabling even more sophisticated medical interventions.

They’re performing cardiac surgeries, reconnecting Fallopian tubes, and replacing hips—all while sitting at a control station that looks more like a high-tech gaming setup than a traditional operating room.

These technological advancements were driven by continuous medical research investments from organizations like NASA and defense research agencies, pushing the boundaries of surgical possibilities. Robotic surgical systems have dramatically reduced patient recovery times and surgical complications, representing a quantum leap in medical technology.

Welcome to the future of medicine.

Global Market Dynamics of Robotic Technologies

You’re standing at the edge of a robotic revolution that’s reshaping global markets faster than you can say “artificial intelligence.”

The global robotics market is on a rocket trajectory, set to more than double by 2030 and hit a staggering $150.84 billion, with Asia Pacific leading the charge and Europe hot on its heels. Industrial robotics are expected to dominate this explosive market growth, particularly in sectors like automotive manufacturing.

While investors are pouring billions into technological advancements, you’ve got a front-row seat to watch how robots are transforming everything from manufacturing to healthcare—and trust me, it’s going to be one wild ride. Specifically, the robot shipment growth in Asia/Australia underscores the rapid global adoption of robotic technologies across diverse industries. Household robot technologies are also emerging as a significant driver of innovation, with market projections indicating substantial growth in consumer robotics.

Market Growth Trajectory

While the robotics market might sound like a nerdy sci-fi fantasy, the numbers tell a different story: we’re looking at a global explosion that’ll make your head spin.

From $71.78 billion in 2025 to potentially $368 billion by 2033, robotics isn’t just growing—it’s practically teleporting into the future.

Industrial robots are muscling into manufacturing, service robots are infiltrating healthcare, and AI is turning machines into smart, adaptable teammates.

Want proof? Automotive lines are already packed with robots, and collaborative bots are working shoulder-to-shoulder with humans.

The growth rate? A whopping 16% annually.

That means robots aren’t just coming; they’re taking over.

And the craziest part? We’re not just talking about cold, mechanical replacements—we’re talking about intelligent, flexible technologies that’ll reshape how we work, live, and solve problems.

Regional Robot Adoption

Robot takeover? Not quite, but robots are definitely spreading globally like tech-powered wildfire.

Check out these regional robot adoption stats that’ll blow your mind:

- Korea leads with a mind-boggling 1,012 robots per 10,000 employees

- Europe’s robot density is climbing steadily at 219 units

- China’s pushing hard with 276,288 robot units installed annually

- North America’s holding steady at 197 robots per 10,000 workers

Different regions have different robot vibes.

Asia’s racing ahead, driven by demographic challenges and tech hunger.

Europe’s methodically automating manufacturing and automotive sectors.

North America’s moving slower but surely, with tech advances pushing industrial efficiency.

The future isn’t about robots replacing humans—it’s about robots working alongside us, making our jobs smarter, faster, and weirdly more human.

Technological Investment Trends

As technology sprints forward like a caffeinated cheetah, the global robotics market is transforming from a niche curiosity into a full-blown economic powerhouse. You’re witnessing a massive investment surge that’ll make your head spin. Companies are dropping serious cash into AI, robotics simulation, and cutting-edge hardware development.

| Investment Area | Market Impact | Growth Projection |

|---|---|---|

| AI Technologies | Transformative | 16% CAGR |

| Robotics Simulation | Innovative | 30% Sales Increase |

| Hardware Development | Disruptive | $150B Market by 2030 |

Want proof? The robotics market is set to double from $71.78 billion to $150.84 billion by 2030. Key players like NVIDIA and UiPath are leading the charge, pushing boundaries in everything from healthcare to warehouse logistics. It’s not just technology—it’s a full-blown revolution happening right under our noses.

Emerging Applications Beyond Traditional Sectors

When cutting-edge technology breaks free from factory floors, it discovers whole new playgrounds of possibility. Robots aren’t just industrial workhorses anymore—they’re branching into territories that would’ve seemed like sci-fi just decades ago.

Consider how robots are reshaping different landscapes:

- Healthcare robots performing delicate surgeries with superhuman precision

- Delivery bots zipping through city streets, transforming logistics

- Educational robots turning complex STEM concepts into playful learning experiences

- Home assistants that do more than just vacuum—they’re becoming personal support systems

These machines aren’t replacing humans; they’re extending our capabilities, filling gaps we didn’t even know existed.

They’re smart, adaptable, and increasingly nuanced—less cold mechanical arms, more intelligent collaborators ready to tackle challenges across unexpected frontiers.

Technological Convergence: AI, IoT, and Robotics

The magic happens when technology’s puzzle pieces start clicking together—and in healthcare, that means AI, IoT, and robotics are forming an incredible team that’s about to blow your mind.

Imagine surgical robots guided by AI’s lightning-fast diagnostic skills, while IoT sensors track every microscopic detail in real-time. These technologies aren’t just cool; they’re revolutionizing patient care by making medical procedures more precise, faster, and safer.

Want to know the wild part? AI can now diagnose diseases more accurately than human experts, and robotics can perform surgeries with superhuman precision.

It’s like having a genius doctor and a steady-handed mechanic working together inside your body. The future isn’t coming—it’s already here, transforming healthcare from reactive to predictive, one smart algorithm and robotic movement at a time.

Workforce Evolution in the Age of Automation

You’re stepping into a workforce transformed by automation, where your skills are your most valuable currency.

As robots and AI become your new colleagues, you’ll need to master the art of human-machine collaboration, continuously upgrading your abilities to stay ahead of the technological curve.

Your future success hinges on embracing continuous learning, developing adaptable skills like creativity and problem-solving, and understanding that the most valuable workers won’t compete with machines, but will learn to work seamlessly alongside them.

Skills Demand Shifts

Because robots are quietly reshaping every industry, workers today face an unprecedented skills revolution that demands constant reinvention.

Your career survival kit now looks radically different than a decade ago.

Here’s what you need to know:

- Technical skills aren’t just nice-to-have—they’re your new baseline (AI proficiency is the new literacy)

- Soft skills like creativity are your secret weapon against automation

- Adaptability isn’t optional; it’s your professional oxygen

- Continuous learning isn’t a recommendation—it’s survival strategy

You’re not just competing with humans anymore; you’re competing with algorithms that work 24/7.

The jobs of tomorrow? They don’t even exist yet.

Human-Robot Collaboration

When robots and humans start dancing together on the factory floor, it’s not just sci-fi fantasy—it’s the new workplace reality.

You’re witnessing a revolution where machines don’t replace workers, but team up with them. Cobots are fundamentally workplace partners that handle repetitive tasks while you focus on complex problem-solving.

They’re smart enough to detect potential collisions and adapt to changing environments, making collaboration safer than ever.

But here’s the kicker: this isn’t about job elimination. It’s about job transformation.

As automation takes over mundane tasks, you’ll shift into roles requiring creativity, critical thinking, and emotional intelligence.

Think of cobots as your high-tech assistants, not your replacements—they’re here to make your work life smoother, not obsolete.

Continuous Learning Imperative

The factory floor’s robot dance has a sequel—and it’s playing out in your career trajectory. Automation isn’t just replacing jobs; it’s reshaping how you’ll work forever. Your survival depends on continuous learning, and here’s why:

- 20 million workers will retrain in new careers in the next 3 years

- 65% of data processing tasks could be automated by 2027

- Workers aged 18-24 are 129% more worried about AI job displacement

- Only 1% of companies feel they’ve mastered AI adoption

You’re not just competing with robots—you’re learning to dance alongside them.

Upskilling isn’t optional; it’s your professional oxygen. Will you adapt or become workforce roadkill?

The choice is crystal clear: keep learning, or get left behind in the technological dust storm that’s rewriting every career playbook.

Challenges and Future Horizons of Robotic Integration

While robots might seem like sci-fi fantasy, they’re rapidly transforming healthcare’s landscape—and not everyone’s thrilled about it. The road to robotic integration isn’t smooth; it’s riddled with skepticism, cost barriers, and technological growing pains. But hey, disruption’s never easy, right?

| Challenge | Potential Solution |

|---|---|

| High Costs | Strategic Investment |

| Workforce Resistance | Training & Collaboration |

| Skill Gaps | Educational Partnerships |

| Regulatory Uncertainty | Adaptive Frameworks |

| Technology Dependence | Robust Cybersecurity |

You’re looking at a future where precision meets compassion, where machines enhance—not replace—human expertise. Sure, there are hurdles: expensive systems, nervous staff, complex regulations. But the potential? Massive. Imagine diagnostic tools that never get tired, surgical assistants with superhuman accuracy, and healthcare delivery that’s faster, smarter, more efficient. The robots are coming—and they’re bringing hope, not just hardware.

People Also Ask

Can Robots Completely Replace Human Workers in Manufacturing and Healthcare?

You can’t fully replace human workers with robots in manufacturing and healthcare, as they lack empathy, complex decision-making skills, and adaptability in nuanced situations.

How Much Does a Typical Industrial or Surgical Robot Cost?

Robotic rates reveal remarkable ranges: you’ll find industrial robots priced from $10,856 to $100,000, while surgical systems like da Vinci can cost $1-2.5 million, depending on complexity and features.

Are Robotic Systems Safe to Work Alongside Human Employees?

You’ll need proper safety protocols, training, and engineering controls to minimize risks. While robots pose hazards, following recommended guidelines can help guarantee safe human-robot collaboration in workplace environments.

What Technical Skills Are Required to Operate Advanced Robotic Technologies?

Practice makes perfect! You’ll need advanced technical skills like precise wrist articulation, console operation knowledge, surgical planning abilities, and proficiency in suturing techniques to effectively operate complex robotic technologies.

How Quickly Are Robotic Technologies Evolving Across Different Industries?

You’ll see robotic technologies rapidly transforming industries, with market values projected to grow over 13% annually, expanding from manufacturing to healthcare, electronics, and pharmaceuticals within just a few years.

The Bottom Line

You’ve seen robots evolve from clunky factory arms to precision surgical instruments. Tomorrow’s world won’t just be automated—it’ll be intelligently choreographed by machines that think, learn, and adapt. Are you ready to dance with technology that’s smarter than yesterday’s wildest dreams? Buckle up: the robotic revolution isn’t coming. It’s already here, transforming everything you thought you knew about human potential.

References

- https://www.autodesk.com/design-make/articles/history-of-industrial-robots

- https://ifr.org/ifr-press-releases/news/record-of-4-million-robots-working-in-factories-worldwide

- https://www.wevolver.com/article/what-are-robotic-assembly-lines-history-components-advantages-limitations-applications-and-future

- https://www.autodesk.com/design-make/articles/industrial-robotics

- https://www.bbntimes.com/technology/the-evolution-of-the-assembly-line-continues-with-robotics

- https://www.progressiveautomations.com/blogs/news/the-evolution-of-automation

- https://www.firgelliauto.com/blogs/actuators/what-is-the-evolution-and-history-of-automation

- https://mikekalil.com/blog/industrial-automation-evolution/

- https://kfactory.eu/the-industrial-revolution-short-history-of-manufacturing/

- https://ifr.org/ifr-press-releases/news/top-5-global-robotics-trends-2025