We’re basically trying to build a human from scratch, which means cramming millions of years of biological evolution into circuits and precision parts. Every tiny component—from ultra-smart sensors to muscle-mimicking actuators—requires breakthrough engineering. It’s like teaching a machine to walk, think, and react like a human, but with silicon instead of cells. Want to know how deep this robotic rabbit hole goes? Stick around.

Advanced Sensor Technologies Drive Up Costs

When it comes to humanoid robots, advanced sensors are like the nervous system of a very expensive, very complicated robot brain. Professional humanoid robots like Sophia represent cutting-edge technological investments in sensor integration.

Our sensor fusion approach isn’t cheap. These high-tech eyes and ears cost a fortune – we’re talking LiDARs that can track movement with insane precision, sensor fusion technologies combine diverse sensors for comprehensive environmental understanding, vision systems that process visual data faster than you can blink, and motion control systems that run between $1,100 to $1,650.

Robotics sensors: bleeding-edge tech that costs a small fortune, but separates elite machines from glorified gadgets.

Our cost analysis reveals that hardware eats up 45% of a robot’s budget, with sensors being the hungriest line item. Sensor development costs can escalate quickly as researchers push the boundaries of robotic perception and intelligence.

Want autonomous navigation? Prepare to pay. Want real-time environmental processing? Your wallet’s going to feel it.

These sensors aren’t just components; they’re the difference between a glorified toy and a machine that can actually interact with the world.

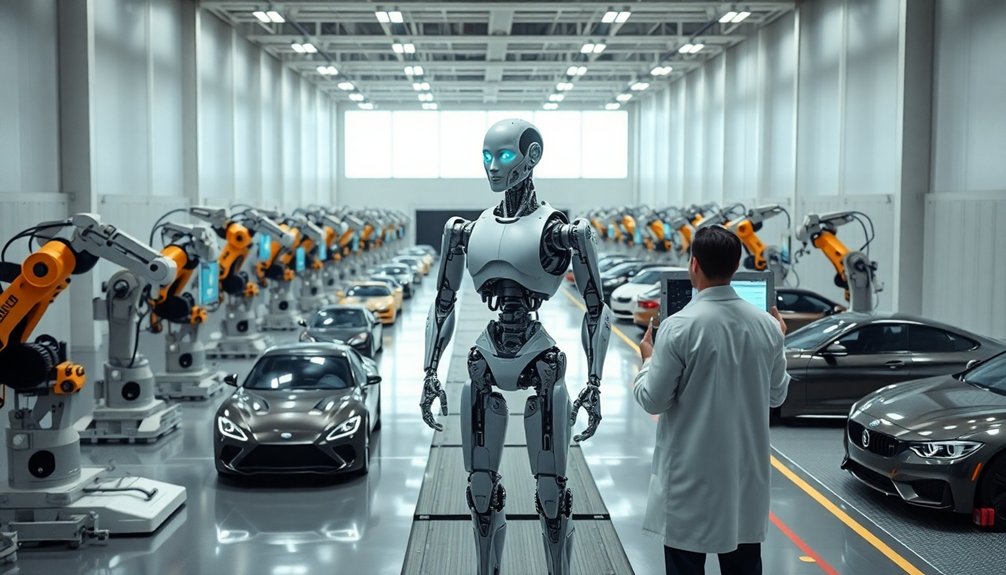

Complex Actuator Engineering and Precision Mechanics

We’ve got a serious engineering puzzle on our hands with humanoid robot actuators: making these mechanical muscles small, powerful, and precise enough to mimic human movement without costing a small fortune. Power density advances in permanent magnet technologies have dramatically reduced the historical performance gap between hydraulic and electric actuators, enabling more compact and efficient robotic joint designs. Smart material integration allows engineers to develop actuators with embedded sensing capabilities, enhancing the robot’s adaptive movement and control precision. Servo motor mechanics play a crucial role in translating computational complexity into nuanced, biomimetic joint performance.

Imagine trying to engineer a mechanical hip joint that can pirouette like a ballet dancer while handling the sudden load of catching a falling object—that’s the kind of precision we’re talking about.

Our engineers are wrestling with motor complexity that would make most mechanical designers weep, designing joint mechanics that can translate computational instructions into fluid, lifelike motion.

Precision Joint Mechanics

The mechanical heartbeat of humanoid robots pulses through their precision joints—those intricate, minuscule marvels that transform rigid metal into something eerily lifelike. We’re talking about articulating joints that demand surgical-level engineering precision. Electrical muscle stimulation enables robotic systems to create muscle-like contractions that mimic biological movement. Hydraulic actuators breathe life into these mechanical muscles, allowing robots to move with an almost unsettling human-like grace. The hip joint’s multi-actuator design enables complex biomechanical movements that push the boundaries of robotic locomotion. Electrical motor advancements have dramatically improved the precision and responsiveness of these intricate mechanical systems.

| Joint Complexity | Material Challenge | Performance Impact |

|---|---|---|

| High precision | Specialized alloys | Smooth motion |

| Intricate design | Custom bearings | Enhanced stability |

| Adaptive mechanics | Advanced composites | Terrain flexibility |

Creating these joints isn’t just engineering—it’s mechanical poetry. Each movement requires microsecond calculations, custom-fabricated components, and materials that can withstand incredible stress. We’re fundamentally building mini mechanical miracles that translate mathematical algorithms into fluid, responsive motion. Who said robots can’t dance?

Motor Complexity Challenges

Because building a robot that moves like a human isn’t just engineering—it’s mechanical wizardry—actuator complexity becomes our ultimate design challenge.

Robotic actuators are the muscles of mechanical movement, and they’re wickedly hard to perfect. We’re constantly wrestling with energy consumption and precision that would make a Swiss watchmaker sweat. Degrees of freedom significantly influence the complexity of these intricate mechanical systems.

Our core challenges include:

- Electric vs. electro-hydraulic trade-offs that demand constant innovation

- Balancing torque output with weight and efficiency

- Transmission systems that can handle extreme mechanical stress

- Precise sensory integration for real-time motion control

- Material selection that doesn’t compromise performance or cost

These intricate mechanical puzzles transform robot design from simple mechanics into a high-stakes dance of engineering brilliance—where every millimeter and milliwatt matters. The recent development of Quasi-Direct-Drive actuators demonstrates how cutting-edge research continuously pushes the boundaries of robotic motion efficiency.

Advanced Movement Engineering

When precision meets raw mechanical power, humanoid robot movement transforms from clunky automation into something eerily human-like.

We’re talking about advanced movement engineering that’s more art than science. Actuator customization techniques let’s design robots that move with shocking grace, using everything from electric motors to spring-assisted mechanisms.

Energy efficiency strategies mean we’re not just making robots move—we’re making them move smart. Imagine joints that adapt on the fly, sensing and responding like a human athlete.

It’s not just about raw power anymore; it’s about creating mechanical limbs that can think, react, and flow. We’re bridging the gap between machine and human movement, one precisely engineered actuator at a time.

Tactile neural networks enable robotic hands to process sensory data with millisecond-level precision, transforming mechanical motion into intelligent adaptation.

Who said robots can’t dance?

Material Science and Structural Design Expenses

We’re fundamentally trying to engineer a human-shaped machine that won’t fall apart the moment it tries to pick up a coffee mug—which means choosing materials that can handle serious mechanical stress without costing more than a luxury sports car. Industrial robot costs range significantly depending on complexity, which directly impacts the engineering challenges of creating a humanoid robot. According to Goldman Sachs, the manufacturing costs for these robots have dramatically dropped from $50k-$250k to $30k-$150k, representing a significant cost reduction in the industry.

Our material science challenges boil down to finding the right balance between strength, weight, and cost, fundamentally creating a skeleton that’s part superhero, part budget spreadsheet.

Imagine designing something that can withstand repeated movements, sensor integrations, and constant mechanical strain, all while keeping the price tag from triggering a corporate heart attack—that’s the razor’s edge we’re walking in humanoid robotics.

Complex Component Selection

Let’s be real: building a humanoid robot isn’t like assembling a plastic action figure. Our complex component selection process demands precision, creativity, and serious cash.

We’re talking about intricate decisions that make or break robotic performance:

- Component scalability requires strategic thinking about how parts will interact and evolve

- Material versatility means finding substances that can handle extreme mechanical stress

- Custom parts often cost exponentially more than standard components

- Sensor and actuator integration demands millimeter-level engineering

- Prototype iterations eat through development budgets faster than a hungry algorithm

We’re fundamentally creating mechanical life forms that need to move, think, and survive in unpredictable environments. The projected cost reduction from $90,000 to $10,000 by 2040 underscores the critical importance of strategic component engineering.

Each design choice is a calculated risk between breakthrough innovation and budget-busting complexity.

Advanced Structural Engineering

From the microscopic dance of components to the macro challenge of building a robot that doesn’t fall apart, structural engineering is where dreams of mechanical life meet cold, hard physics.

We’re talking advanced material innovations that make engineers sweat and wallets cry. Every curve, joint, and connection requires insane precision—imagine trying to build a human-like machine that won’t topple over like a drunk toddler.

Sustainable manufacturing practices help, but let’s be real: these aren’t your grandpa’s tin toys.

Finite element analysis, 3D modeling, and relentless load testing transform raw materials into potential mechanical miracles.

The result? Robots that might—just might—survive more than five minutes without catastrophic structural failure.

Physics is brutal, but we’re getting smarter.

Precision Material Requirements

While most people think robots are just fancy metal puppets, the reality of their material science is a mind-bending economic puzzle that’ll make your wallet sweat.

We’re diving into the nitty-gritty of material sourcing and weight considerations that make humanoid robots absurdly expensive. It’s not just about slapping metal and plastic together—it’s a delicate dance of engineering economics.

Key challenges in robotic material selection:

- Balancing durability with lightweight performance

- Maneuvering complex sourcing from global markets

- Managing astronomical costs of advanced materials

- Ensuring structural integrity under diverse conditions

- Minimizing weight without compromising strength

Material choices aren’t just technical—they’re financial gambles where every gram and molecule impacts the final price tag.

Who knew robots were basically walking, talking economic experiments?

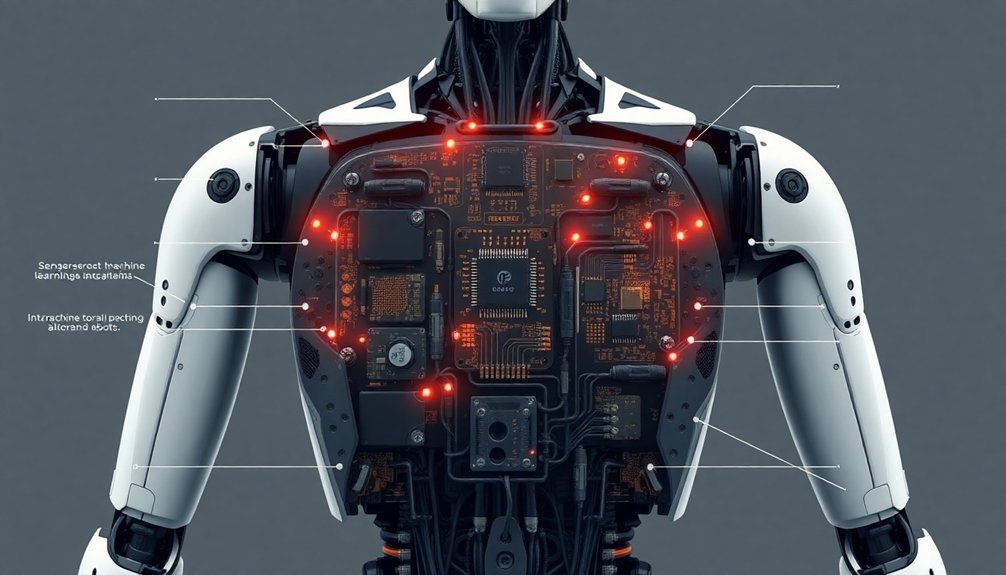

Computational Processing and AI Development Investments

Because building a humanoid robot isn’t just about metal and motors, the real magic—and wallet-draining complexity—happens in its digital brain. Our AI computational investments aren’t for the faint of wallet: developing algorithms that let robots think and adapt requires serious computational muscle.

| Complexity Level | Computational Power | Cost Impact |

|---|---|---|

| Basic Learning | Low | $50K-$100K |

| Adaptive AI | Medium | $250K-$500K |

| Advanced Autonomy | High | $750K-$1.5M |

| Machine Learning | Ultra-High | $2M-$5M |

| Cognitive Reasoning | Extreme | $5M-$10M |

We’re fundamentally creating digital neurological networks that can process real-time sensory data, learn from experiences, and make split-second decisions. Algorithmic efficiency isn’t just a buzzword—it’s the difference between a robot that bumbles and one that brilliantly navigates complex environments. Want a smart robot? Get ready to invest serious computational cash.

Human-Like Movement Simulation Research Expenditures

When we talk about making robots move like humans, we’re not just playing with fancy toys—we’re wrestling with one of engineering’s most complex puzzles. Simulating human-like locomotion isn’t just about programming steps; it’s a mind-bending dance of kinematic adaptation and sensor fusion.

We’re fundamentally teaching machines to think and move like us, which sounds cool until you see the astronomical research costs.

Key challenges in human-like movement simulation include:

- Capturing nuanced biomechanics through ultra-precise motion capture

- Developing feedback mechanisms that mimic neural responsiveness

- Creating algorithmic efficiency for dynamic environment adaptation

- Analyzing complex motion heuristics in real-time

- Ensuring simulation fidelity across unpredictable scenarios

The result? Millions spent decoding how humans actually move.

Battery and Power Management System Challenges

From decoding human movement to powering those robotic limbs, we’ve got another engineering Everest to climb: keeping these mechanical marvels juiced up and running. Battery efficiency isn’t just a challenge—it’s a high-stakes game of electrical Jenga. We’re talking about cramming massive power into tiny spaces while managing heat, preventing fires, and ensuring consistent performance.

| Challenge | Impact | Solution Strategy |

|---|---|---|

| Heat Management | Performance Degradation | Advanced Thermal Systems |

| Battery Size | Mobility Limitations | High-Density Materials |

| Power Distribution | Inconsistent Operation | Smart Energy Routing |

| Safety Risks | Potential System Failure | Robust Protective Mechanisms |

| Environmental Adaptability | Reduced Functionality | Resilient Design Approaches |

Our power management systems must be smarter than a Swiss Army knife—compact, adaptable, and ready for anything. Think lightweight tech that can handle temperature swings, moisture, and constant movement without breaking a sweat.

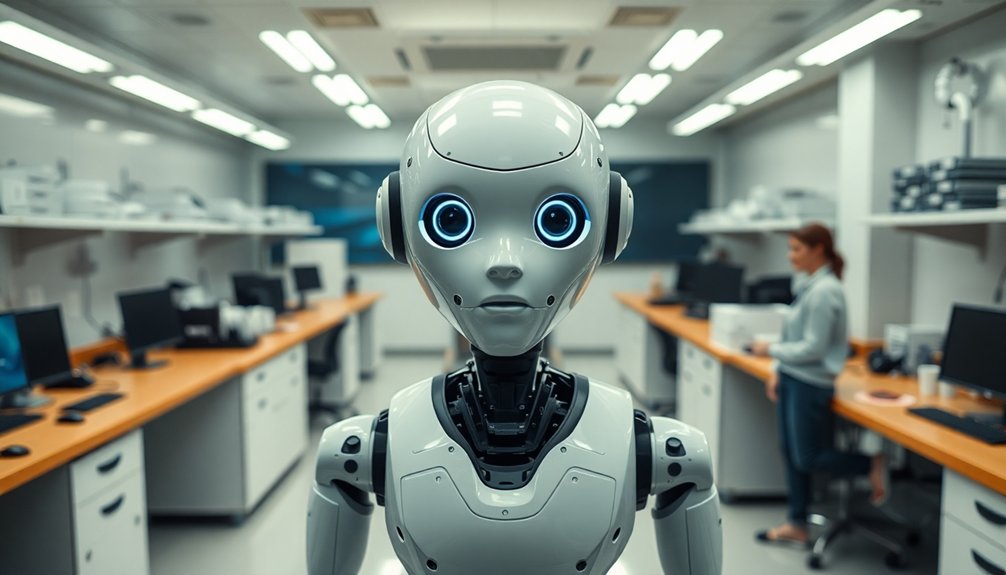

Machine Learning and Neural Network Programming Costs

Machine learning for humanoid robots isn’t just complicated—it’s like teaching a giant, expensive toddler to think and move without breaking something expensive.

We’re talking about neural networks that require mountains of data, crazy-powerful computing hardware, and teams of brilliant engineers who basically speak robot in their sleep.

Designing these AI systems is less like programming and more like sculpting intelligence from pure mathematical willpower, with each model costing more than some people’s annual salary.

AI Training Complexity

Because building a humanoid robot isn’t just about slapping some metal and circuits together, AI training complexity represents the brain-melting challenge that makes robot developers lose sleep.

We’re talking about a mind-bending process of data processing and model optimization that turns brilliant engineers into caffeine-fueled zombies.

The real complexity comes down to:

- Teaching machines to think like humans (but without the existential crisis)

- Maneuvering the labyrinth of neural network integration

- Handling real-time processing in unpredictable environments

- Converting massive datasets into actionable intelligence

- Balancing computational power with practical adaptability

Training an AI isn’t just expensive—it’s like sending a rocket to Mars, except the rocket has feelings and might decide to reorganize your kitchen while you’re sleeping.

Neural Network Development

Artificial intelligence doesn’t just grow on trees—it’s engineered with neural networks that cost more than most people’s annual salaries.

We’re talking serious cash for creating machine brains that can think and learn. Neural network efficiency isn’t cheap: high-end hardware like GPUs eat budgets for breakfast, while data processing challenges require specialized experts who don’t work for minimum wage.

Developing these complex algorithmic systems means juggling interdisciplinary skills, from AI engineering to robotics programming.

Every line of code, every training dataset, every optimization tweak adds up—and we mean WAY up. Want a robot that can recognize your facial expression or navigate a room?

Get ready to open your wallet wide. Neural networks transform machines from dumb machines to learning entities, but that intelligence comes with a hefty price tag.

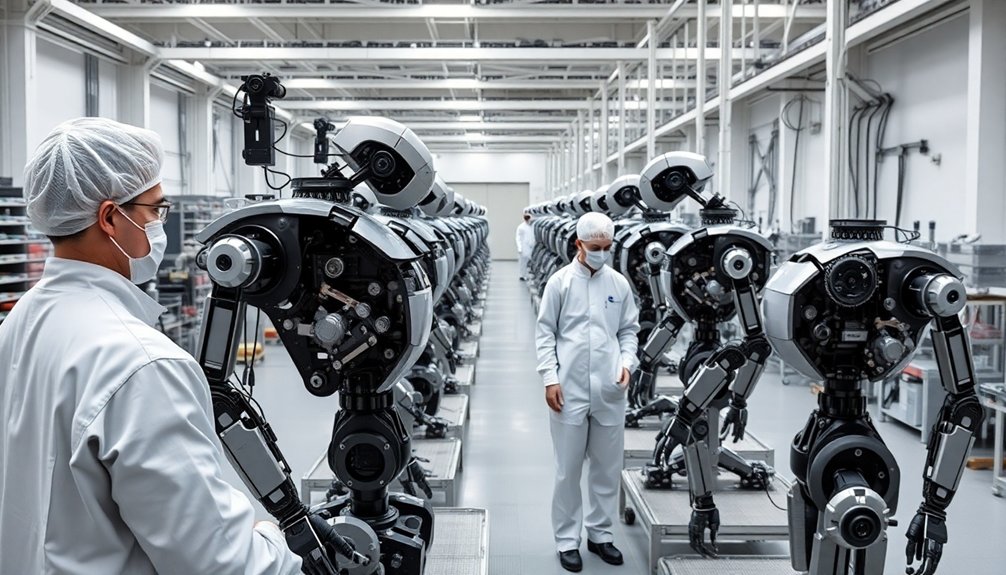

Precision Manufacturing and Quality Control Processes

When it comes to creating humanoid robots that don’t fall apart the moment they take a step, precision manufacturing isn’t just important—it’s everything.

Our supply chain and regulatory compliance depend on obsessive attention to detail that would make a Swiss watchmaker look sloppy.

Why are humanoid robots so expensive? Here’s the inside scoop:

- Robotic assembly requires microscopic precision down to fractions of millimeters

- Every component must meet insanely tight tolerance standards

- Automated inspection systems catch defects humans would completely miss

- Quality control isn’t just a process—it’s a relentless pursuit of perfection

- One tiny manufacturing error can tank an entire multi-million dollar robot project

We’re basically creating mechanical humans that can’t accidentally disintegrate.

No pressure, right?

Integrated Robotic Control System Development

If you think teaching a toddler to walk is complicated, try programming a multi-million-dollar humanoid robot to navigate the real world without face-planting. Control system integration is where rocket science meets dance choreography. We’ve learned that Control Optimization isn’t just about smooth movements—it’s about creating intelligent, responsive systems that can adapt faster than a chameleon changes colors.

| System Component | Performance | Complexity |

|---|---|---|

| Sensor Network | High | Advanced |

| Processing Unit | Critical | Sophisticated |

| Actuator Control | Precise | Intricate |

| Communication | Seamless | Dynamic |

| Fail-Safe Mechanisms | Robust | Essential |

System Integration demands more than just connecting parts. It requires understanding how each component communicates, anticipates, and recovers from unexpected scenarios. We’re fundamentally teaching machines to think on their feet—literally. The computational power needed? Astronomical. The potential? Mind-blowing.

Research and Prototype Testing Overhead Expenses

Because building a humanoid robot isn’t cheap, we’ve got to talk about the jaw-dropping expenses behind these mechanical marvels.

Humanoid robots: where cutting-edge technology meets wallet-crushing complexity in a high-stakes financial dance.

Prototype development is a financial rollercoaster where costs can skyrocket faster than a rocket launch. We’re talking serious cash for every tiny component and testing phase.

Our research reveals the hidden complexity of robot creation:

- Prototype material selection drives costs into the stratosphere

- Testing facility requirements demand specialized environments

- Component complexity increases exponential price tags

- Iterative design means constant reinvestment

- Safety validation requires mega-expensive scenarios

From custom parts costing thousands to validation processes that eat budgets alive, creating a humanoid robot isn’t for the financially faint-hearted.

We’re fundamentally building walking, talking money pits that promise future innovation—if we can afford to get them off the drawing board.

People Also Ask

Why Can’t Humanoid Robots Be Made Cheaper Like Regular Household Electronics?

We can’t make humanoid robots as cheap as household electronics due to complex manufacturing challenges and current technology limitations that demand specialized, high-precision components and extensive custom engineering.

Do Humanoid Robots Actually Provide Enough Value to Justify Their High Costs?

We’ve analyzed the value assessment and find that humanoid robots’ cost-benefit ratio shows promise, especially as technological advancements could reduce expenses and increase efficiency across multiple industrial applications.

How Long Will It Take for Humanoid Robot Prices to Become Affordable?

We’ll soon trade our coffee-guzzling coworkers for metallic colleagues! Market trends and technology advancements predict humanoid robot prices dropping to $13,000-$17,000 by 2030, making robotic workforce integration increasingly feasible.

Can Hobbyists or Small Companies Realistically Build Their Own Humanoid Robots?

We can tackle DIY robotics challenges through open-source solutions, but building humanoid robots remains complex and costly. Collaboration and incremental innovation might help hobbyists make modest progress.

What Makes Humanoid Robots More Expensive Than Other Types of Industrial Robots?

We find humanoid robots costlier due to their sensing technology and actuator complexity, which require intricate multi-axis movement systems and advanced sensors that dramatically increase mechanical and electrical design challenges.

The Bottom Line

We’ve just scratched the surface of humanoid robotics’ astronomical price tag. Building a machine that moves like us isn’t just expensive—it’s mind-blowingly complex. From quantum-level sensors to AI brains that cost more than some luxury cars, we’re fundamentally trying to manufacture a synthetic human. Sure, it sounds like sci-fi, but right now, creating a walking, talking robot is like building a rocket that does interpretive dance.

References

- https://qviro.com/blog/how-much-does-a-humanoid-robot-cost/

- https://www.installbaseforum.com/forums/threads/the-prosumer-model-stays-winning-goldman-sachs-estimates-humanoid-robot-manufacturing-cost-30k-to-150k-per-unit-lets-look-at-the-competition.2505/

- https://standardbots.com/blog/how-much-do-robots-cost

- https://www.futuremanagementgroup.com/en/humanoid-robots-how-much-will-they-cost-part-4/

- https://www.futurobots.com/the-real-cost-of-building-a-humanoid-robot/

- https://www.robotshop.com/collections/professional-humanoid-robots

- https://www.generationrobots.com/en/190-advanced-sensors-and-tools-for-robotics

- https://top3dshop.com/robots/humanoid-robots/

- https://www.hardwarefyi.com/resources/humanoid-robotics-engineering-actuators/

- https://www.mdpi.com/2076-0825/14/5/243