Feedback loops are your robot’s secret sauce, turning dumb machines into smart problem-solvers. Think of them like a robot’s nervous system — sensors gather data, controllers process it, and actuators make split-second adjustments. They’re how robots learn to navigate tricky environments, correct mistakes on the fly, and basically become mini-brain machines. Want to know how robots might just outsmart humans? Stick around, and you’ll see the magic behind their intelligence.

Understanding the Fundamentals of Feedback Loops

While robots might seem like cold, calculating machines, they’re actually brilliant mimics of biological systems—and feedback loops are their secret sauce. Sensor fusion techniques integrate multiple data streams, allowing robots to create a more comprehensive understanding of their environment.

These clever control systems use sensors to track every tiny movement, making real-time adjustments that keep robots dancing through complex environments. Think of it like a super-smart thermostat that constantly checks room temperature and tweaks heating accordingly.

Feedback control systems aren’t just about precision—they’re about adaptability. When environmental changes pop up unexpectedly, robots with robust feedback mechanisms can pivot faster than a Silicon Valley startup.

Your robot isn’t just following pre-programmed instructions; it’s thinking, responding, and correcting itself in milliseconds. Sensors become its eyes, ears, and neural network, transforming rigid programming into dynamic, responsive intelligence.

Core Components of Robotic Feedback Mechanisms

Because robots aren’t just fancy tin cans moving in predictable patterns, their feedback mechanisms are more like sophisticated biological nervous systems. Actuator technologies are advancing to mimic human muscle performance with increasing precision.

Think of these robotic control systems as having three key players: sensors (the eyes and ears), controllers (the brain), and actuators (the muscle). Sensors grab environmental data, controllers crunch those numbers using smart algorithms, and actuators make things happen. It’s like a high-tech dance where every movement gets instant feedback.

Robotic systems: a high-tech ballet of sensors, controllers, and actuators dancing with precision and real-time feedback.

You’ve got two flavors of these systems: open-loop (basically shooting in the dark) and closed-loop (constantly course-correcting).

PID controllers are the rockstars here, helping robots stay stable and perform like pros. Want precision? These feedback mechanisms are your ticket to robotic awesomeness.

How Sensor Data Drives Adaptive Robot Behavior

Imagine a robot that doesn’t just blindly follow orders, but actually learns and adapts in real-time—that’s the magic of sensor-driven behavior.

Sensor data isn’t just numbers; it’s the nervous system of robotic control systems. When cameras, LIDAR, and force sensors feed information back into the robot’s “brain,” something incredible happens. These feedback loops transform rigid machines into dynamic learners.

Want a robot that can stack blocks more efficiently? Its sensors capture every tiny error, adjusting movements microsecond by microsecond. Autonomous vehicles use this same trick, fusing sensor data to navigate complex environments with shocking precision.

It’s like giving robots a superpower: the ability to understand their world and instantly recalibrate. Your future coworker won’t just obey—it’ll think, adjust, and improve.

Sensor fusion techniques enable robots to integrate multiple sensory inputs, creating a more comprehensive understanding of their environment.

Adaptive robot behavior isn’t science fiction anymore; it’s happening right now.

Precision Control Through Closed-Loop Systems

As robots push the boundaries of precision, closed-loop systems emerge as the unsung heroes of modern control technology.

These feedback loops are the secret sauce that transform clunky machines into razor-sharp performers. Imagine a robot maneuvering complex terrain—it’s constantly comparing its actual position to its intended path, making micro-adjustments faster than you can blink.

PID controllers are the brain’s behind-the-scenes wizards, calculating real-time corrections based on current, past, and potential future errors.

Sensors like cameras and LIDAR become the robot’s eyes and ears, feeding critical environmental data that facilitates precision control.

Whether it’s an autonomous vehicle threading through traffic or a surgical robot performing delicate procedures, closed-loop systems guarantee your mechanical companions adapt, respond, and execute tasks with mind-blowing accuracy. Neural network algorithms enable robots to continuously learn and refine their movement patterns, enhancing their adaptive capabilities through advanced sensor technologies.

Mathematical Models Behind Feedback Control

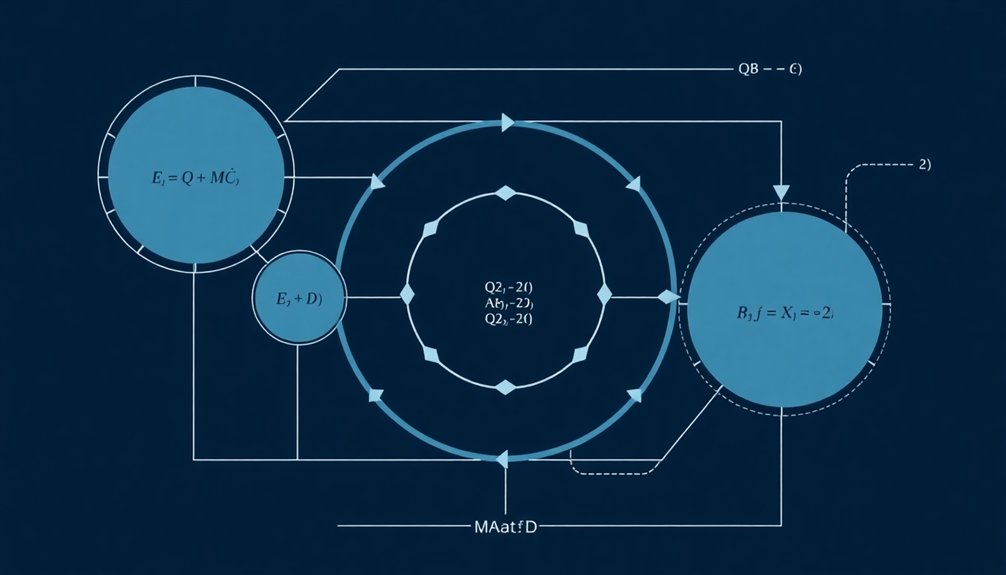

Mathematical models aren’t just fancy squiggles on a whiteboard—they’re the secret language robots use to understand and navigate their world.

In feedback control systems, these models translate complex robot behaviors into mathematical equations that predict and manage movement. Take the PID controller, for instance: it’s like a robot’s brain, constantly adjusting its actions using proportional, integral, and derivative gains to stay on track.

Mathematical models decode robot behavior, translating complex motions into precise, brain-like control equations.

Stability analysis becomes the robot’s internal compass, helping it detect potential system wobbles before they become full-blown malfunctions.

You’ll find these mathematical models working behind the scenes, transforming raw sensor data into precise, calculated responses.

Want to know how robots think? It’s all about turning chaos into controlled, predictable motion—one equation at a time.

Real-World Applications Across Robotic Domains

You’ve seen robots welding car parts with machine-like precision, but have you considered how feedback loops are quietly revolutionizing industrial automation and medical robotics? Depth estimation techniques allow robots to understand their precise environment, enhancing their ability to navigate and interact with complex systems. From assembly lines that self-correct in milliseconds to robotic surgeons that can navigate human tissue with less tremor than a seasoned neurosurgeon, feedback control isn’t just a technological trick—it’s reshaping how we perceive precision and human-machine collaboration.

Industrial Automation Precision

When precision meets robotics, industrial automation transforms from a clunky dream to a razor-sharp reality. Feedback loops are the secret sauce that makes industrial robots dance with breathtaking accuracy.

These smart systems can adjust their actions based on real-time sensor data, turning manufacturing into a symphony of mechanical perfection. Tactile sensors enhance robotic perception by providing instantaneous environmental feedback.

- Robotic arms now nail positioning with less than 0.1 mm error

- Automated inspection systems catch defects before they escape

- Collaborative robots sense human presence and adjust instantly

Imagine machines that learn and adapt on the fly, constantly fine-tuning their movements. They’re not just tools; they’re intelligent partners in production.

By continuously monitoring and correcting their performance, these robots eliminate human error, boost efficiency, and make precision look effortless.

Who said robots can’t be smart? They’re rewriting the rules of manufacturing, one microscopic adjustment at a time.

Medical Robotic Innovations

Because surgery used to mean massive incisions and weeks of recovery, medical robots are flipping the script on how we think about human healing.

These high-tech healers use feedback loops to transform patient care, turning complex procedures into precise, minimally invasive interventions.

Imagine robotic prosthetics that adjust grip strength in milliseconds or surgical systems that merge camera and sensor data to navigate human anatomy with surgical precision.

Medical robots aren’t just tools; they’re intelligent partners in healthcare.

Feedback control systems let remote surgeons perform operations across continents, while rehabilitation robots customize recovery plans in real-time.

These aren’t sci-fi fantasies—they’re happening now.

Want proof? The da Vinci Surgical System and i-limb prosthetics are already proving that when technology meets human anatomy, miraculous things can happen.

Companion robots are emerging as potential support systems that can address loneliness and provide consistent care for vulnerable populations.

Challenges in Implementing Effective Feedback Loops

Despite robotic control systems looking sleek and sophisticated on the surface, they’re wrestling with some seriously tricky feedback loop challenges that can turn precision engineering into a technological tug-of-war.

You’re maneuvering through a minefield of potential issues in robotic control:

- Sensor noise turns crisp measurements into fuzzy guesswork

- External disturbances create unpredictable system interruptions

- Tuning controller gains becomes a delicate high-stakes balancing act

Imagine trying to drive a car where the steering wheel randomly decides to ignore your input – that’s what unstable feedback loops feel like for robots.

Robotic control: A high-stakes dance where precision meets chaos, and feedback loops become technological wildcards.

Your carefully designed control system can quickly transform from a precision instrument into a chaotic mess. Latency, noise, and unexpected environmental forces conspire to undermine even the most meticulously engineered feedback mechanisms.

The difference between a robot that performs flawlessly and one that stumbles lies in how effectively you can anticipate and mitigate these inherent system challenges.

Complex sensor networks provide a critical nervous system for robots to process and respond to real-time movement data, helping mitigate some of these feedback loop challenges.

Performance Optimization Strategies

Robot whisperers, listen up: fine-tuning robotic control systems isn’t just about fancy algorithms—it’s about outsmarting physics itself.

Performance optimization hinges on smart feedback loops that transform sensor data into lightning-fast decisions. Your secret weapon? The PID controller—a triple-threat tech marvel that tackles current errors, corrects past mishaps, and predicts future challenges. It’s like having a robotic brain that learns, adapts, and adjusts in milliseconds.

Imagine autonomous vehicles maneuvering through chaotic traffic or industrial robots executing complex tasks with surgical precision. These aren’t sci-fi fantasies—they’re real-world applications of adaptive feedback mechanisms. Neural networks are fundamental to this transformative approach, enabling robots to dynamically adapt to unpredictable environments and continuously improve their performance.

Advanced Sensing Technologies for Robotic Feedback

Precision engineering meets sci-fi-level perception in advanced robotic sensing technologies. Your future mechanical friends are getting seriously smart, thanks to feedback systems that blur the line between machine and sentient being.

These cutting-edge technologies transform robots from clunky automatons into responsive, intelligent agents through:

- LIDAR and computer vision that literally “see” the world in breathtaking detail

- Exteroceptive sensors detecting forces and interactions with superhuman precision

- Sensor fusion techniques that combine multiple data streams for unprecedented accuracy

Machine learning amplifies these advanced sensing technologies, allowing robots to learn and adapt in real-time. Neuromorphic computing enables robots to process sensory information more efficiently, mimicking the intricate neural networks of biological brains.

Imagine a robot that doesn’t just react, but understands and anticipates—like a hyper-intelligent Swiss Army knife with a PhD in environmental awareness.

The future isn’t just coming; it’s already here, watching, learning, and probably judging our human limitations.

Learning and Improvement Through Continuous Monitoring

You’ve seen robots fumble and fail, but what if they could learn from every mistake like a nerdy kid obsessed with getting better?

Adaptive learning mechanisms let robots track their own performance, constantly comparing what they did against what they should’ve done, turning each task into a chance to level up their skills.

Adaptive Learning Mechanisms

When machines start learning from their own mistakes, that’s when things get truly interesting. Feedback loops are the secret sauce of adaptive learning mechanisms, transforming robots from rigid automatons into dynamic problem-solvers. They track:

- Current state vs. desired performance

- Past errors as learning opportunities

- Real-time adjustments that spark improvement

Your robotic buddy isn’t just following programmed instructions anymore; it’s actively analyzing its actions, gathering data, and refining its approach.

Imagine a robotic arm that learns to stack blocks with increasing precision, each failed attempt teaching it something new. These adaptive mechanisms aren’t just cool tech—they’re a glimpse into a future where machines don’t just execute tasks, but understand them.

Performance Tracking Strategies

How do robots transform from clumsy machines into precise performance masters? Through feedback loops, that’s how. These clever circuits continuously track a robot’s performance like a hyper-attentive coach, comparing actual outputs to desired targets in real-time. Your robot isn’t just moving; it’s learning.

PID controllers are the secret sauce here, computing errors and guiding corrections with mathematical precision. Imagine a robotic arm that stacks blocks, analyzing each placement, adjusting its grip, angle, and speed after every attempt. It’s not just repeating—it’s improving.

Sensor data becomes the robot’s brain, transforming clunky movements into surgical precision.

Performance tracking isn’t about perfection; it’s about constant adaptation. Your robot’s ability to learn isn’t just impressive—it’s revolutionary. Who knew machines could be such quick studies?

Continuous System Evolution

Because robots aren’t static lumps of metal anymore, continuous system evolution represents the cutting edge of intelligent machine design. Feedback loops transform robotic systems from rigid automatons into adaptive learners that grow smarter with every task.

Your robotic companion will:

- Absorb sensor data like a knowledge sponge

- Refine performance through continuous learning

- Adjust strategies faster than you can blink

Imagine a robot that doesn’t just repeat programmed motions, but actively improves its approach. These intelligent machines analyze their own performance, identify weaknesses, and self-correct in real-time.

Future Trends in Robotic Control Systems

As robotic control systems hurtle toward an increasingly intelligent future, the next decade promises a technological metamorphosis that’ll make today’s robots look like clunky wind-up toys.

Advanced feedback loops will transform robotic systems from rigid machines into nimble, adaptive response machines. You’ll see sensor technologies evolve so dramatically that robots will process environmental data faster than you can blink.

Imagine machines that learn and adjust in milliseconds, powered by neuromorphic computing that mimics brain processes. Digital twins will simulate complex scenarios, allowing engineers to test and optimize control strategies before real-world deployment.

With 5G connectivity enabling near-instantaneous communication, these robots won’t just react—they’ll anticipate.

The future isn’t about replacing humans; it’s about creating intelligent partners that complement our capabilities in ways we’re only beginning to understand.

People Also Ask About Robots

How Is a Feedback Loop Used in Robotics?

You’ll use a feedback loop to continuously monitor your robot’s performance, comparing its current state to the desired output and making real-time adjustments using sensors, ensuring precise and adaptive movement.

What Is the Purpose of a Feedback Loop in a Control System?

You’ll use feedback loops to continuously compare your system’s actual output with the desired target, allowing real-time adjustments that help you maintain peak performance by minimizing errors and adapting to changing conditions.

Why Is Feedback Control Important in Robotics?

With 85% of industrial robots relying on feedback control, you’ll find it vital for precision, safety, and adaptability. You’ll need it to help robots dynamically adjust, learn from errors, and interact seamlessly with changing environments and human collaborators.

What Is the Function of Feedback in Control System?

You’ll use feedback to continuously compare your system’s actual output with the desired target, calculating errors and making real-time adjustments that help your robotic system maintain precise performance and adapt to changing environmental conditions.

Why This Matters in Robotics

You’ve just witnessed how robots are becoming smarter than your average appliance. Like a nervous system learning and adapting, feedback loops are turning machines into responsive, thinking creatures. They’ll soon predict your needs before you do, tweaking performance with every interaction. Don’t be surprised when your robot buddy understands you better than most humans. The future isn’t just coming—it’s already calibrating itself, one sensor at a time.