Table of Contents

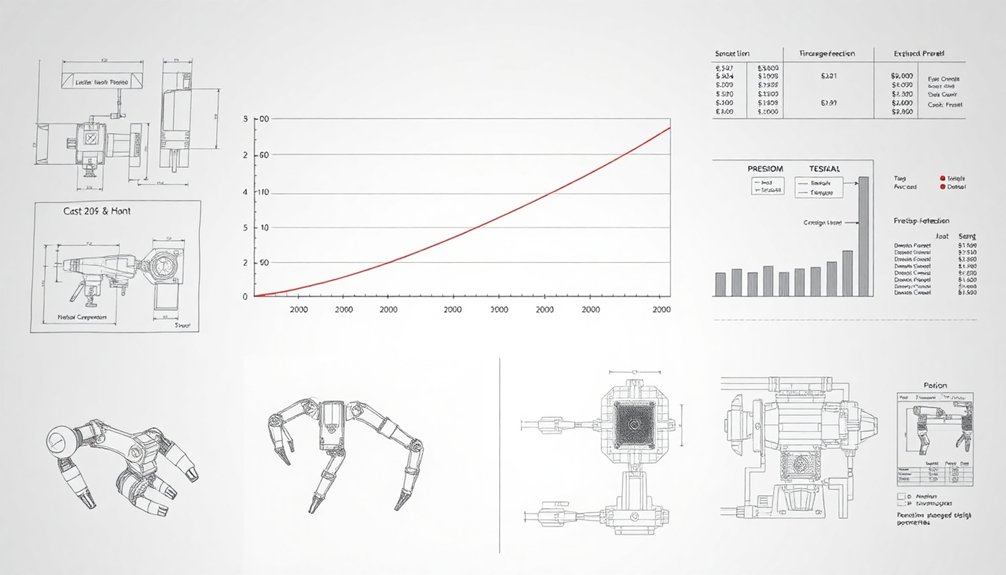

Building a humanoid robot isn’t cheap. You’re looking at $30,000 to $150,000 per robot, with research models skyrocketing to $500,000. Advanced sensors, complex actuators, and cutting-edge AI drive up costs like crazy. Expect to burn through serious cash on engineering talent, specialized components, and endless testing. But don’t panic—prices are predicted to nosedive to $13,000 by 2030. Curious about how these robotic price tags might transform? Stick around.

Bill of Materials: Decoding Component Expenses

When you’re diving into the world of humanoid robots, the first thing that’ll smack you in the wallet is the jaw-dropping price tag.

These mechanical marvels aren’t cheap, with current models ranging from $30,000 to a whopping $150,000.

Want to know why? It’s all about the components. Advanced actuators that give robots their mobility can push prices sky-high, especially for models that can walk or climb.

Advanced sensor technology like sophisticated visual and tactile perception systems significantly contribute to the overall manufacturing complexity and cost. Battery management systems play a crucial role in determining the robot’s operational efficiency and long-term performance costs.

Chinese-made parts can help trim costs, but specialized features like dexterous hands or cutting-edge vision systems quickly add zeroes to the bill.

The good news? Experts predict these prices will nosedive by 2030, potentially dropping to around $13,000-$17,000 as mass production kicks in and technology becomes more commoditized.

Robot revolution, here we come—if we can afford the ticket. Global market competition is intensifying, with countries like China and the US racing to develop more affordable humanoid robots.

Research and Development: The Hidden Investment

You’ve heard about cool robots, but have you ever wondered what it actually costs to create one from scratch?

Building a humanoid robot isn’t just about slapping together some metal and circuits—it’s a massively expensive treasure hunt where brilliant researchers spend hundreds of thousands of dollars chasing technological breakthroughs that might revolutionize how we interact with machines.

Currently, the manufacturing cost of these robots has dramatically dropped from $50,000-$250,000 to $30,000-$150,000, representing a significant cost reduction milestone in the industry. By 2050, experts predict humanoid robot costs will plummet from $200,000 to just $50,000 per unit, making these technological marvels increasingly accessible to industries and consumers alike.

The real investment isn’t just in components, but in the relentless human curiosity that pushes engineers to transform sci-fi fantasies into something you could potentially high-five in your living room someday. Humanoid robots are evolving beyond mere machines, becoming intelligent companions capable of understanding and adapting to human emotional needs.

High R&D Expenses

Because building a humanoid robot isn’t just about slapping together some metal and circuits, the real heavyweight champion of expenses is R&D—a financial marathon that’ll make your wallet weep.

We’re talking eye-watering costs that start at $100,000 and can rocket past $500,000, depending on how fancy you want your mechanical friend to be. Those price tags come loaded with expensive components, cutting-edge AI software, and teams of genius engineers who don’t work for pizza and dreams. Neural network development has become a critical expense, with advanced cognitive systems driving up research costs significantly. Sensor fusion technologies play a crucial role in increasing development complexity and costs, requiring sophisticated integration of multiple perceptual systems.

Want a robot that can actually do something useful? Prepare for endless testing, iteration, and customization that’ll drain your bank account faster than a smartphone battery.

And just when you think you’re done, technological advancements will whisper, “Not so fast, money bags—time to upgrade.”

Technical Complexity Costs

The labyrinth of technical complexity in humanoid robotics isn’t for the faint of wallet or weak of mind.

Building a robot isn’t like assembling IKEA furniture—it’s more like designing a spaceship with 5,000 intricate parts. Want smooth movements? That’ll cost you. Each degree of freedom adds complexity faster than your credit card can handle.

Advanced sensors, precise actuators, and cutting-edge cameras transform your robotic dream into a financial nightmare. Neural network adaptations enable robots to learn and adjust movements, adding another layer of sophisticated complexity to the development process. Wheels might be cheaper than legs, but who wants boring transportation when you can have a walking, talking machine?

Metal components drive up costs, while high-end processing guarantees your robot isn’t just a fancy paperweight. Industrial robot pricing ranges from $20,000 to over $100,000, making the financial investment as complex as the technical challenge.

It’s a delicate dance between engineering brilliance and budget reality—where every component whispers, “Ka-ching!”

Innovation Investment Challenges

When investors peer into the robotic crystal ball, they’re not just gambling on metal and circuits—they’re fundamentally betting on humanity’s next evolutionary leap.

The humanoid robot market isn’t just a technological playground; it’s a high-stakes financial rollercoaster. Prices have plummeted from $250,000 to around $150,000 per unit, with research models still commanding a jaw-dropping $500,000 price tag.

But here’s the kicker: costs are nosediving faster than anyone predicted—a 40% decline that’s making tech nerds and Wall Street hawks sit up and take notice.

Asia’s manufacturing prowess is driving this cost revolution, transforming humanoid robots from sci-fi fantasies into tangible investments. By 2035, we’re looking at a $38 billion market that could reshape entire industries.

Collaborative machine intelligence is accelerating innovation, pushing the boundaries of what autonomous systems can achieve beyond traditional manufacturing constraints.

Want in on the ground floor?

Software Engineering: Intelligent Systems Pricing

Software engineering for humanoid robots isn’t just about lines of code—it’s about creating intelligent systems that don’t bankrupt your wallet. Global robotics research indicates that advanced interactive models like Sophia are pushing boundaries of technological integration. You’re looking at a world where R&D robots cost between $100,000 and $500,000, with software eating up a chunky 15% of total development costs. Want advanced sensors and AI interaction? Prepare to open your checkbook.

But here’s the twist: prices are dropping faster than a robot’s first attempt at walking. Mass production and vertical integration are making these mechanical marvels more accessible.

From research bots to home companions, you’ll soon find humanoid robots priced between $5,000 and $20,000. The future isn’t just coming—it’s getting cheaper, smarter, and more within reach.

Think of it as Moore’s Law meets your living room. These robots are projected to become cost-effective workforce solutions at just a fraction of traditional human labor expenses.

Manufacturing Complexity and Production Costs

You’re about to discover why building a humanoid robot isn’t just expensive—it’s like trying to assemble a rocket-powered Swiss Army knife with parts sourced from the moon.

The manufacturing complexity will make your engineering team’s hair turn gray faster than a Silicon Valley startup burns through venture capital, with each precision component driving up costs like a runaway financial algorithm.

Sourcing advanced actuators, sensors, and materials isn’t just a technical challenge; it’s a high-stakes poker game where the chips are cutting-edge technology and the stakes are nothing less than the future of robotic innovation. The extreme precision required for humanoid robots means that even minor deviations can result in massive production costs, dramatically increasing the financial investment needed to bring these technological marvels to life. According to recent industry reports, technical maturity challenges in upper limb technologies significantly contribute to the complexity and cost of developing fully functional humanoid robots.

Component Sourcing Expenses

Building a humanoid robot isn’t just a sci-fi dream—it’s a wallet-crushing reality that’ll make your bank account weep.

Those fancy actuators that help robots move? They’ll set you back anywhere from $30,000 to $150,000.

Want advanced sensors and processing power? Get ready to drop over $200,000.

Your robot’s design matters too—metal components cost way more than cheap plastic parts.

Think sourcing is simple? Think again. Smart manufacturers hunt for low-cost component locations like China to trim expenses.

Each robotic body part—from hands to shoulders—has its own price tag, driving up your total bill of materials.

Economies of scale can help, but you’re still looking at a hefty investment.

Who knew creating a mechanical human could be so expensive?

Manufacturing Technical Challenges

When engineers dream up humanoid robots, they quickly slam into a wall of manufacturing nightmares that would make even the most hardened tech veterans sweat.

The challenges aren’t for the faint of heart:

- Thermal Management: These mechanical humans generate more heat than a laptop in a sauna, demanding complex cooling systems that don’t break the bank.

- Sensor Integration: Cramming advanced sensors into a robot’s body is like trying to fit a supercomputer into a Swiss Army knife — precise, delicate, and mind-bendingly complicated.

- Mechanical Stability: Ensuring these robots don’t topple over like drunk toddlers requires engineering wizardry that balances durability with lightweight design.

Each challenge multiplies production costs and complexity, turning humanoid robot manufacturing into a high-stakes technological chess match where one wrong move means starting over.

Research Development Investments

If you thought building a humanoid robot was just about slapping together some metal and circuits, buckle up for a reality check. The real cost of innovation isn’t just dollars—it’s complexity.

Manufacturing these mechanical marvels now ranges from $30,000 to $150,000 per unit, with costs plummeting faster than you’d expect. Smart design choices like harmonic reducers and strategic component sourcing from China are driving prices down.

By 2030, you’ll see over 250,000 robots rolling off production lines, primarily for industrial grunt work. The secret sauce? Sophisticated vision systems, efficient assembly techniques, and a relentless drive to make robots cheaper than human labor.

Your future workforce might just be made of circuits and servos, and it’ll cost less than your monthly coffee budget.

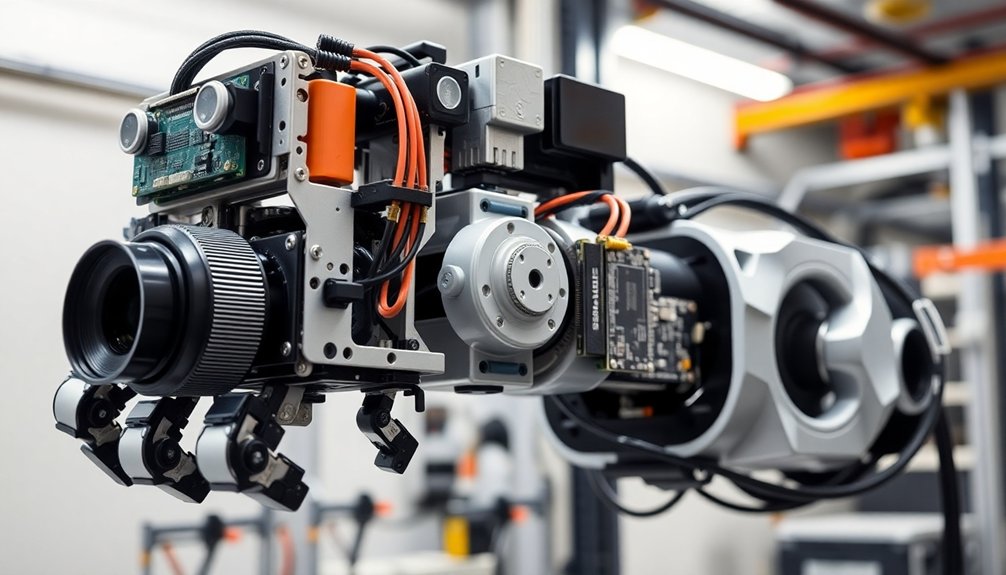

Technology Integration: Sensors and Advanced Capabilities

Sensors are the nervous system of humanoid robots, transforming hunks of metal and wiring into something almost alive. These tiny technological marvels do the heavy lifting of making robots more than just programmed machines:

- Force and torque sensors give robots human-like precision, letting them manipulate objects with surgical accuracy.

- Inertial measurement units (IMUs) help robots maintain balance and respond dynamically, like a gymnast sensing every micro-movement.

- Visual and radar systems turn robots into environmental detectives, mapping spaces and identifying objects with superhuman speed.

Imagine a robot that can feel pressure, track movement, and adapt to changing environments—all without breaking a sweat.

These sensors aren’t just components; they’re the secret sauce that transforms rigid machinery into something eerily intelligent.

Want to create a robot that doesn’t just move, but genuinely perceives? Sensors are your new best friend.

Market Dynamics and Pricing Strategies

As the humanoid robot market accelerates from a nerdy sci-fi fantasy into a multi-billion dollar reality, pricing strategies are becoming the make-or-break factor that’ll determine which robots actually survive the tech thunderdome. Companies are battling it out with wildly different price points, from Tesla’s $120,000 industrial beast to more budget-friendly $10,000 domestic helpers.

| Price Range | Target Market | Key Players |

|---|---|---|

| $10,000-$50,000 | Domestic/Small Business | Startup Innovators |

| $50,000-$150,000 | Industrial/Advanced | Tesla, XPeng |

| $150,000+ | High-End Research | Advanced Robotics Labs |

The market’s diversity reflects a fundamental question: Will robots be luxury tech or everyday tools? With Morgan Stanley predicting a $5 trillion market by 2050, these pricing battles aren’t just about dollars—they’re about defining our robotic future. Who’ll win? The smartest, not just the most expensive.

Future Cost Trajectories: Innovations and Projections

While the sticker shock of humanoid robots might currently make your wallet weep, the future’s looking suspiciously affordable.

Robots are about to get a major price makeover, thanks to some seriously clever innovations:

- AI integration is slashing production costs, turning these mechanical marvels from luxury items into potential everyday companions.

- Mass production will drive prices down faster than a robot on caffeine, with projections suggesting costs could plummet below $20,000 by 2030.

- Modular designs and smarter manufacturing mean you’ll soon be able to upgrade your robot like a smartphone, without breaking the bank.

Think of it like the early days of computers: once prohibitively expensive, now basically disposable.

The robot revolution isn’t just coming—it’s getting a serious discount.

People Also Ask

Can Humanoid Robots Replace Human Workers Entirely in Different Industries?

You’ll find humanoid robots can’t completely replace humans yet, but they’ll likely transform job markets in industries like manufacturing, construction, and warehousing, creating both opportunities and challenges for workers.

How Safe Are Humanoid Robots When Working Alongside Humans?

You’ll find humanoid robots are increasingly safe, with advanced sensors and AI detecting potential hazards. They’re designed to minimize risks, but challenges remain in sensor accuracy and public trust in their collaborative capabilities.

Do Humanoid Robots Require Specialized Maintenance and Training to Operate?

You’ll need specialized training to maintain humanoid robots, as they require understanding complex AI systems, diagnostic skills, and knowledge of their unique mechanical components. Ongoing education is essential for effective operation and maintenance.

What Are the Potential Privacy Risks With Advanced Humanoid Robot Technologies?

Pervasive privacy pitfalls persist with humanoid robots. You’ll encounter risks like unintended personal data collection, sensor surveillance, and potential biometric tracking. They’ll capture your interactions, movements, and environment, compromising your privacy without proper safeguards.

Can Consumers Expect Affordable Humanoid Robots in Their Homes Soon?

You’ll soon see affordable humanoid robots in your home, with models like BYD’s BoYoboD and Tesla’s Optimus targeting prices around $10,000-$30,000, making personal robotic assistants a realistic consumer option by 2026.

The Bottom Line

You’re staring at the future, and it’s not cheap. Humanoid robots are like fancy sports cars—each component screams “expensive engineering magic.” Will the price tag eventually drop? Probably. But right now, you’re looking at a technological moonshot where complex software, precision manufacturing, and cutting-edge sensors create a perfect storm of wallet-draining innovation. Buckle up—the robotic revolution isn’t just coming; it’s already here, and it’s got a price tag to match.

References

- https://www.morganstanley.com/insights/articles/humanoid-robot-market-5-trillion-by-2050

- https://www.idtechex.com/en/research-report/humanoid-robots/1093

- https://www.globenewswire.com/news-release/2025/05/26/3088003/0/en/Humanoid-Robots-Market-Global-Outlook-Report-2025-Key-Market-Dynamics-and-Emerging-Opportunities-through-2035.html

- https://aicompetence.org/humanoid-robots-in-2025/

- https://www.outlookbusiness.com/start-up/deeptech/humanoid-robots-could-cost-just-13000-by-2035-heres-what-that-means-for-global-ai-race

- https://uc.edu/content/dam/refresh/cont-ed-62/olli/s25-handouts/exploring humanoid robots 5.pdf

- https://qviro.com/blog/how-much-does-a-humanoid-robot-cost/

- https://institute.bankofamerica.com/content/dam/transformation/humanoid-robots.pdf

- https://advisor.morganstanley.com/john.howard/documents/field/j/jo/john-howard/The_Humanoid_100_-_Mapping_the_Humanoid_Robot_Value_Chain.pdf

- https://www.goldmansachs.com/insights/articles/the-global-market-for-robots-could-reach-38-billion-by-2035